News

-

Stainless Steel

Stainless Steel (Stainless Steel) is a high-alloy steel that is resistant to corrosion. It has a beautiful surface and does not need surface treatment such as color plating or paint. Therefore, many machinery factories often do not do any paint treatment in order to show that they are stainless s...Read more -

Surface Treatment-Plating

Principle: Electroplating is an electrochemical and redox process. Take nickel plating as an example: the metal part is immersed in the solution of metal salt (NiS04) as the cathode, and the metal nickel plate is used as the anode. After the direct current power supply is turned on, the metal nic...Read more -

Phosphating

Advantages of phosphating The high-temperature manganese phosphating film has the characteristics of dense film layer, good wear resistance, and excellent anti-corrosion and anti-rust performance. Because the phosphating film has a large specific surface area and good adsorption capacity, it is w...Read more -

Three ways of welding

Welding achieves the purpose of joining through the following three ways: 1. Fusion welding – heating the workpieces to be joined to make them partially melt to form a molten pool, and then join after the molten pool is cooled and solidified. If necessary, fillers can be added to assist. It...Read more -

Surface Treatment-Phosphating process

I. Overview: Steel parts (such as fasteners) go through a series of chemical and electrochemical reactions in a solution containing phosphate. The process of forming a phosphate protective film that is difficult to dissolve in water on the surface is called phosphating of steel. . The color of th...Read more -

Several Heat Treatment Methods of Carburizing

The heat treatment process of carburized steel includes preparatory heat treatment and carburizing and quenching process, in which heat treatment includes ordinary normalizing, isothermal normalizing, normalizing + tempering, and isothermal annealing. Carburizing and quenching mainly includes pre...Read more -

Composition characteristics of carburizing steel

The carbon content of carburized steel is generally very low (between 0.15% and 0.25%), which belongs to low carbon steel. Such carbon content ensures that the core of carburized parts has good toughness and plasticity. In order to improve the strength of the core of the steel, a certain amount o...Read more -

Carburizing and quenching-Heat treatment

The main heat treatment process of carburizing steel is generally quenching and low temperature tempering after carburizing. The core of the treated part is a low-carbon martensite structure with sufficient strength and toughness, and the surface layer is hard and wear-resistant tempered martensi...Read more -

Milling Machines and Milling Cutters

There are many shapes of milling cutters, which are used for processing slots and linear contours on ordinary milling machines and CNC milling machines, and for machining cavities, cores, and curved surface shapes/contours on milling and boring machining centers. Generally divided into: 1. Flat e...Read more -

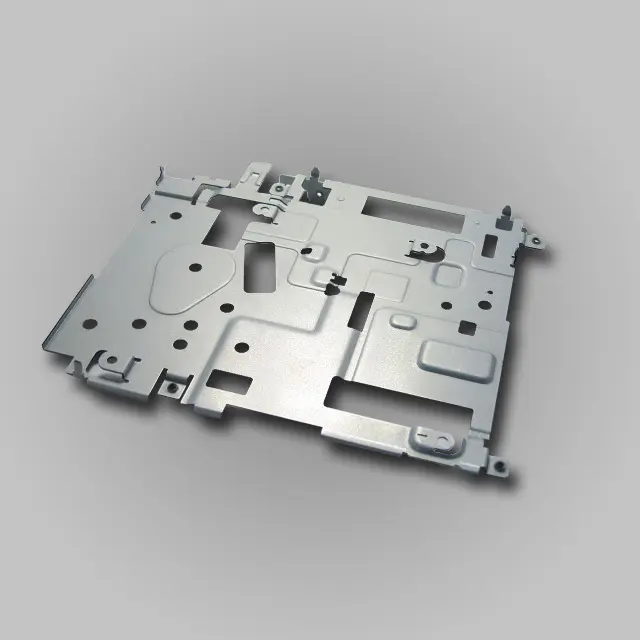

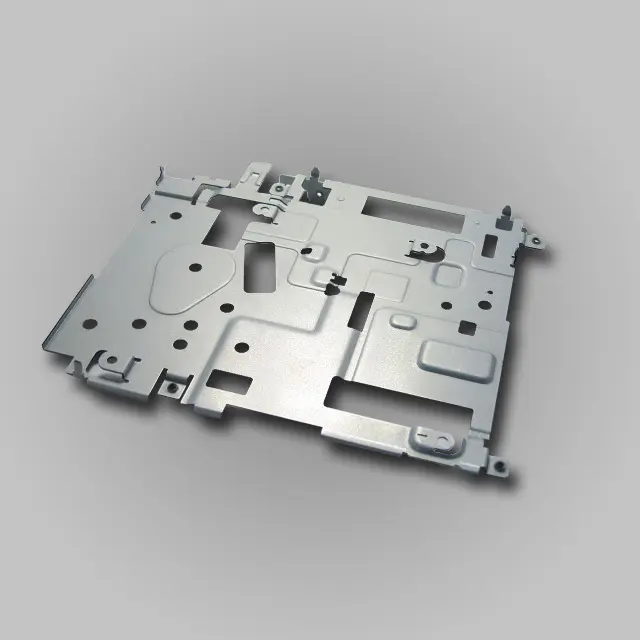

About Stamping

Sheet metal stamping is also known as “stamping”. This is a process that uses a lot of force to change the shape of a flat sheet of metal. The process may also involve punching holes in the metal. Sheet metal stamping is a very common process. In fact, sheet metal stamping is part of ...Read more -

The difference between TIG and Laser welding

1. Different technical principles 1. Laser welding: Laser radiation heats the surface to be processed, and the surface heat diffuses to the inside through heat conduction. By controlling laser parameters such as laser pulse width, energy, peak power and repetition frequency, the workpiece is melt...Read more -

MIG-Welding

Carbon dioxide shielded welding full name carbon dioxide gas shielded arc welding. The protective gas is carbon dioxide (sometimes CO2+Ar mixture), mainly used for hand welding. Due to the special influence of the thermal and physical properties of carbon dioxide gas, when using conventional weld...Read more