News

-

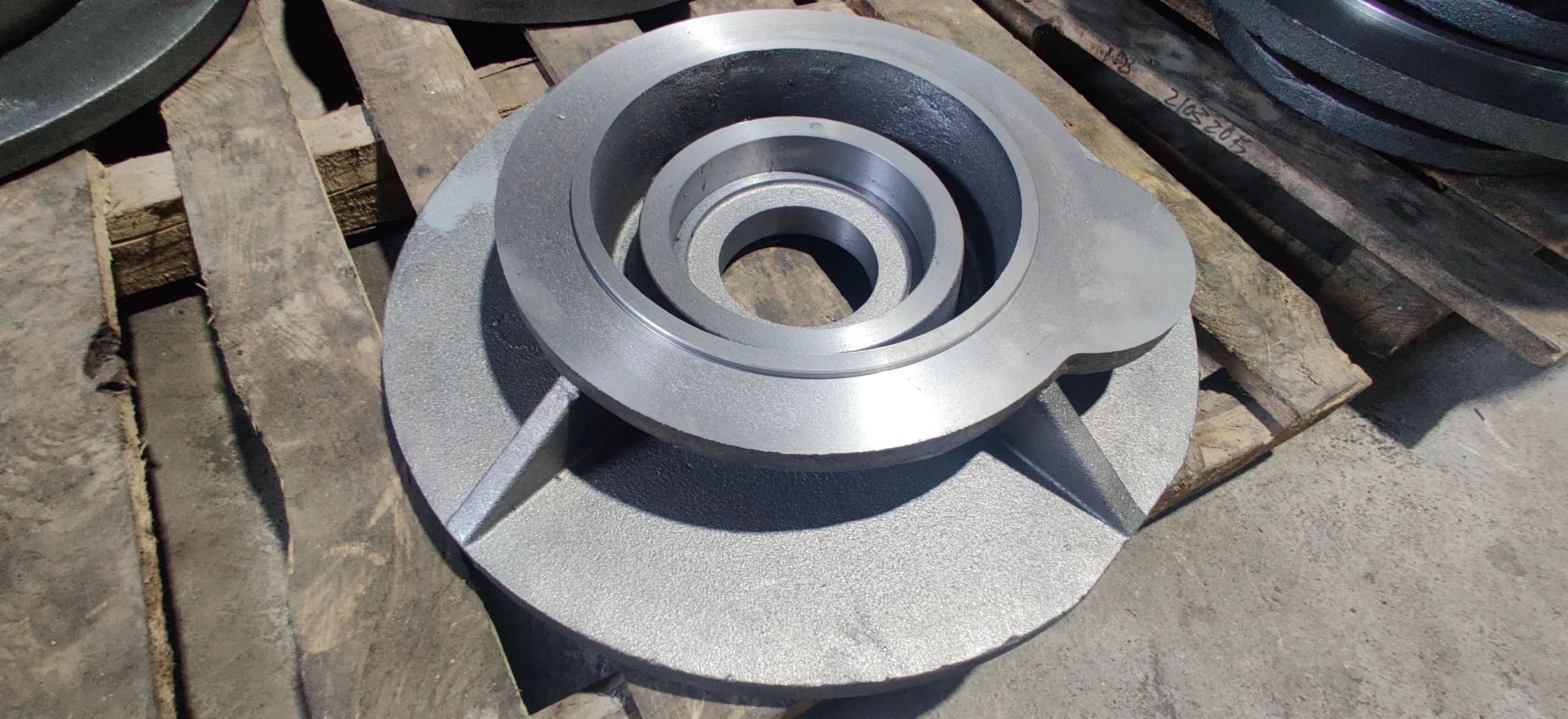

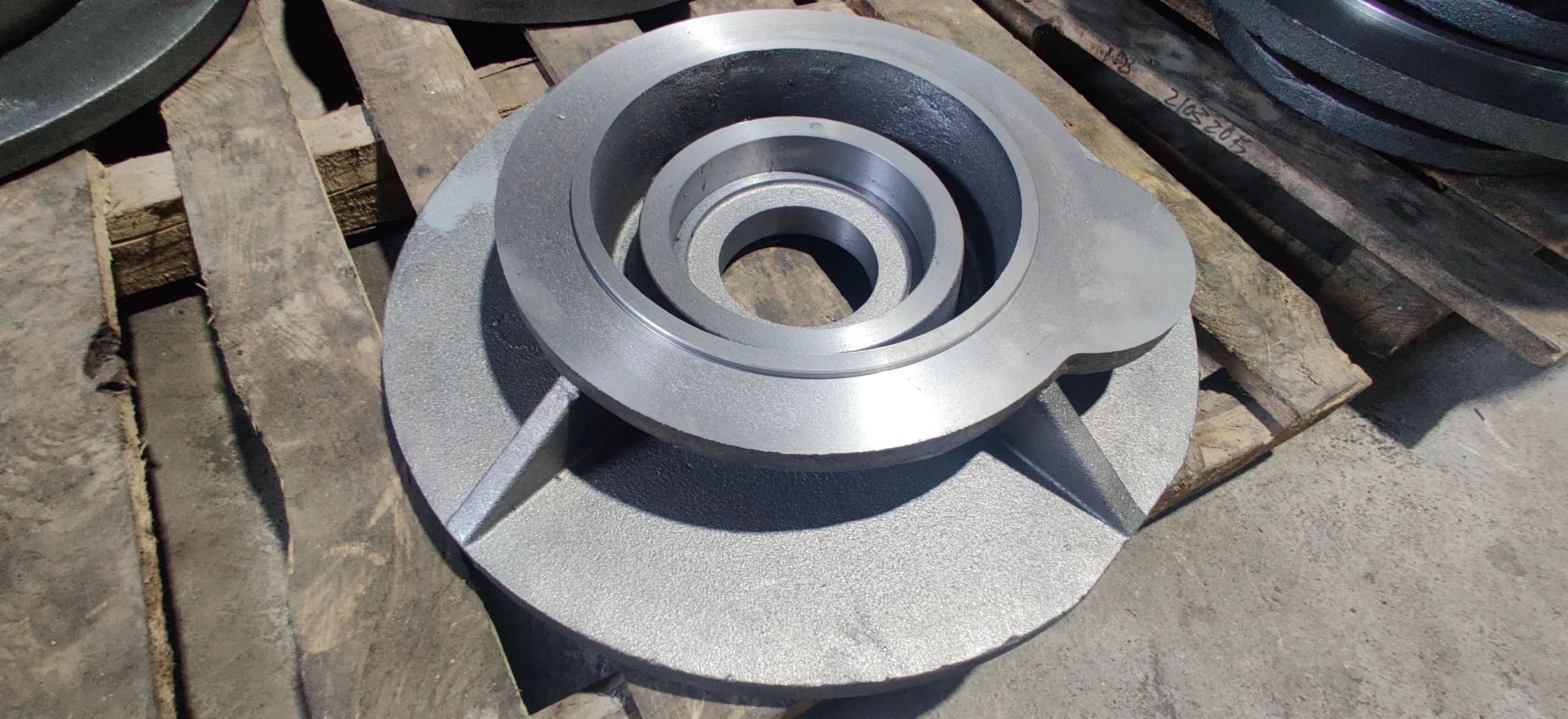

Gray Iron Castings

Gray cast iron refers to cast iron with flake graphite, because the fracture is dark gray when broken, so it is called gray cast iron. The main components are iron, carbon, silicon, manganese, sulfur, and phosphorus. It is the most widely used cast iron, and its output accounts for more than 80% ...Read more -

Should low carbon steel be tempered after carburizing?

1. Carburizing is to place the workpiece made of low-carbon steel or low-carbon alloy steel in a carbon-rich active medium. The commonly used heating temperature is 850~950°C, and keep it warm for several hours, so that the carburizing medium is produced on the surface of the workpiece. Activated...Read more -

Shift Fork

The shift fork belongs to the operating mechanism, which connects and disconnects the transmission mechanism. For example, gear shifting fork, clutch shifting fork, such as changing the position of the slipping gear of the lathe to achieve speed change; or used in the mechanism that controls the ...Read more -

Electrolytic polishing

The technology of using metal workpiece as anode and electrolyzing it in a suitable electrolyte to selectively remove its rough surface and improve the surface finish is also called electrolytic polishing. Electropolishing can increase the corrosion resistance of stainless steel, reduce the resis...Read more -

Analysis of Influencing Factors of Welding Quality

As a modern advanced leading manufacturing technology, welding has been gradually integrated into the main life process of products, that is, from design and development, process formulation, manufacturing and production, to operation and service, failure analysis, maintenance, recycling and othe...Read more -

Xiaoman Solar term

Xiaoman, the eighth solar term in the twenty-four solar terms, is also the second solar term in summer. The name Xiaoman has two meanings. First, it is related to climate precipitation. During the Xiaoman solar term, the torrential rain in the south began to increase, and the precipitation was fr...Read more -

May major events in Neuland

On the evening of May 4, 2023, after the epidemic was lifted, we welcomed the first wave of foreign customers’ visiting, and they’re friends from UK. On May 5th, we went to the factory for in-depth exchanges and discussions on some key issues. Just like today’s good weather, blue sky, whit...Read more -

Material selection for shaft parts

1. Working conditions of shaft parts (1) It is mainly subjected to the compound action of alternating bending and torsional stress during work; (2) There is relative movement between the shaft and the parts on the shaft, and there is friction and wear between them; (3) The shaft will vibrate duri...Read more -

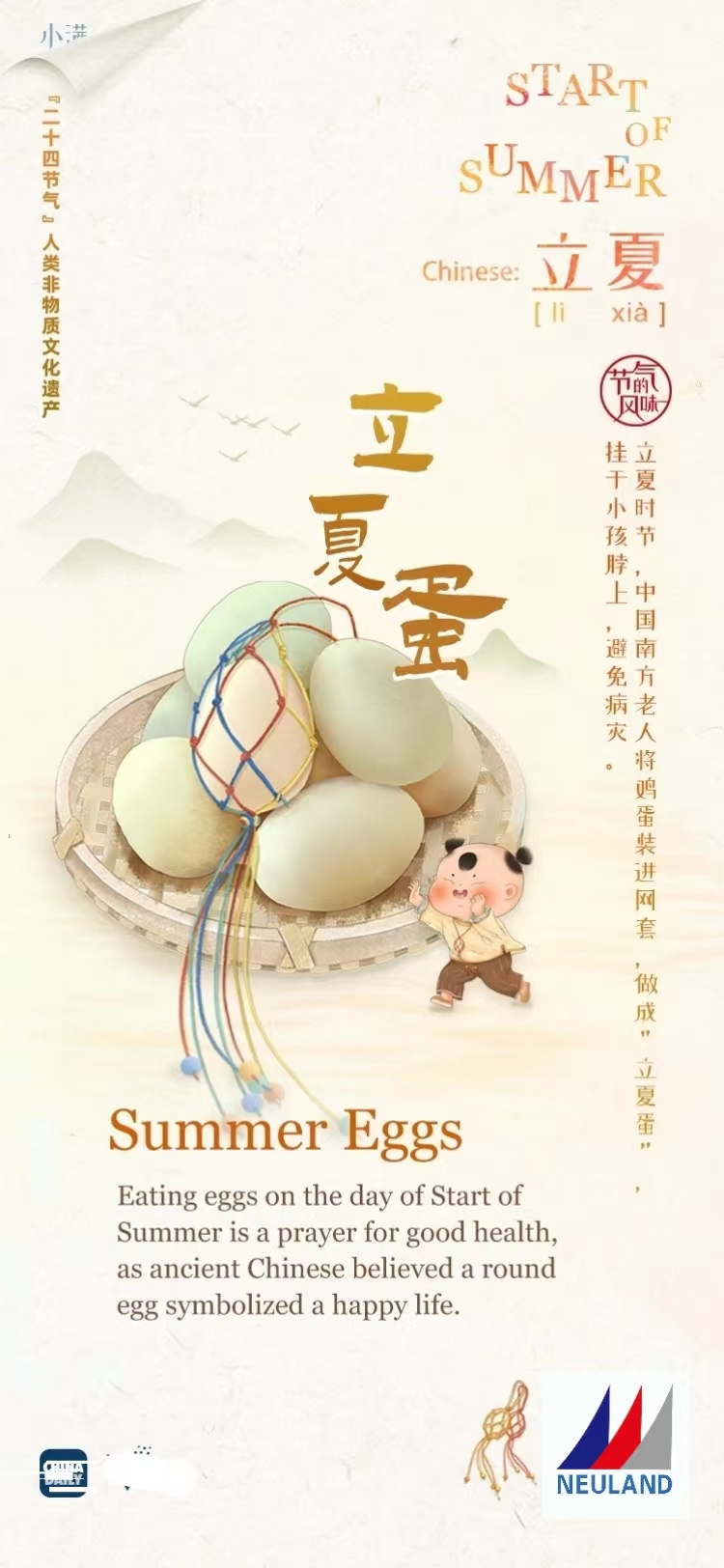

Lixia’s Story-Summer Eggs

As the sun rises on a clear day in early May, millions of Chinese celebrate the start of summer, a traditional festival dating back more than 2,500 years. The holiday is called “Lixia” in Mandarin, and it is considered one of the twenty-four solar terms in the Chinese calendar. Lixia&...Read more -

China Aerospace Day – Development of New Materials in China’s Aerospace Field

(1) Development trend of titanium and titanium alloy materials Titanium alloy has become the most ideal structural material in the aviation industry because of its excellent performance characteristics. Judging from the development trend of materials used in aviation parts in developed countries,...Read more -

Metal Material Process

1. Castability (castability) Refers to the performance of metal materials that can obtain qualified castings by casting methods. Castability mainly includes fluidity, shrinkage and segregation. Fluidity refers to the ability of liquid metal to fill the mold, shrinkage refers to the degree of volu...Read more -

TIG welding

TIG welding technology is based on the principle of ordinary TIG #welding, using argon gas to protect the metal welding material, and through high current to make the welding material melt into a liquid state on the base material to be welded to form a molten pool, so that the welded metal and th...Read more