1. Different technical principles

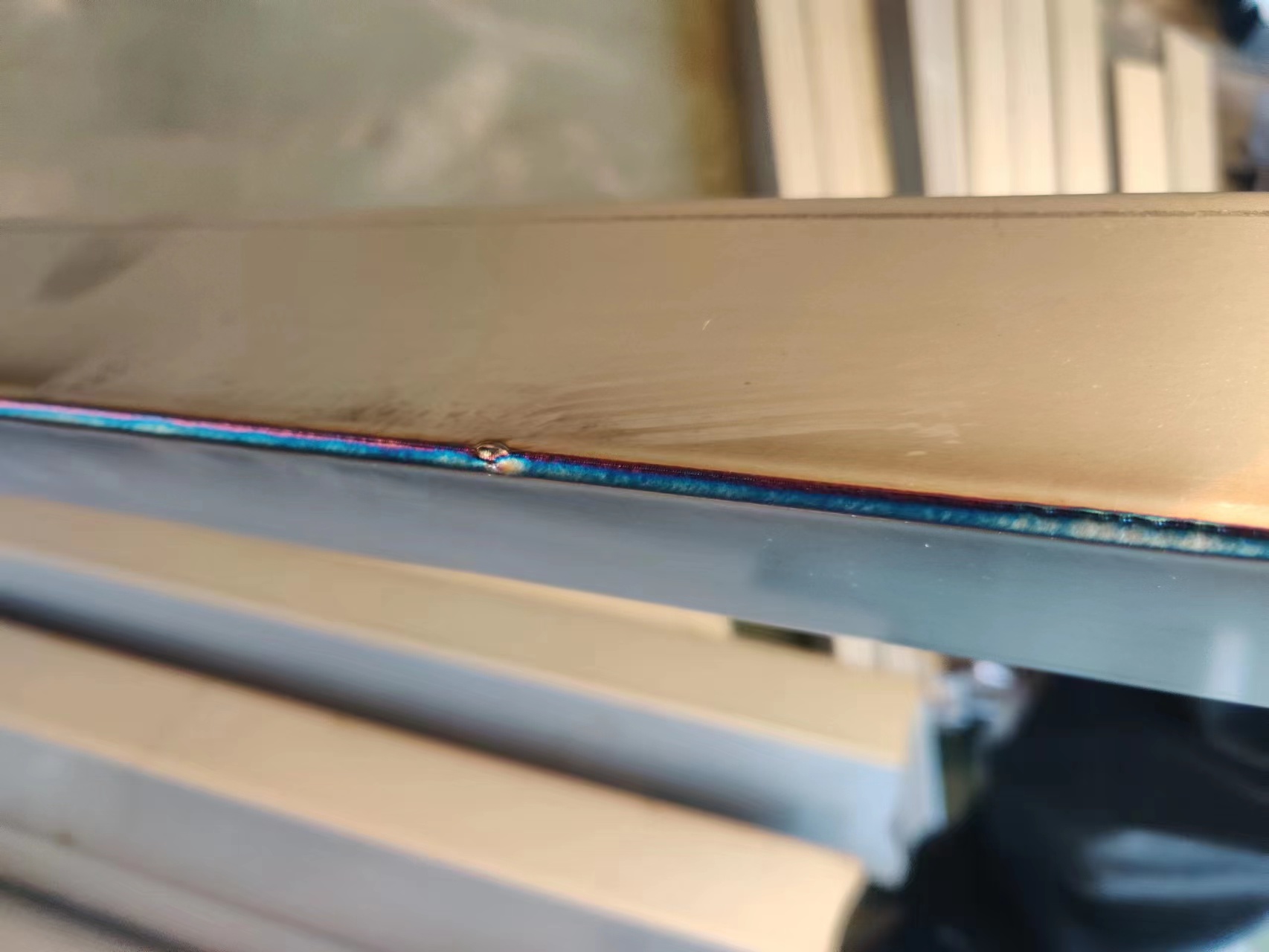

1. Laser welding: Laser radiation heats the surface to be processed, and the surface heat diffuses to the inside through heat conduction. By controlling laser parameters such as laser pulse width, energy, peak power and repetition frequency, the workpiece is melted to form a specific molten pool.

2. Argon arc welding: On the basis of the principle of ordinary arc welding, argon is used to protect the metal welding material, and the welding material is melted into a liquid state on the base material to be welded to form a molten pool through high current, so that the metal to be welded and A welding technique in which the welding material achieves metallurgical combination. Due to the continuous supply of argon gas during high-temperature fusion welding, the welding material cannot be in contact with the oxygen in the air, thereby preventing the oxidation of the welding material.

2. Different fields of application

1. Laser welding: Laser tailor welding technology has been widely used in foreign car manufacturing; laser welding has been widely used in the electronics industry, especially in the microelectronics industry.

2. Argon arc welding: Argon arc welding is suitable for welding easily oxidized non-ferrous metals and alloy steels (mainly welding Al, Mg, Ti and their alloys and stainless steel); suitable for single-sided welding and double-sided forming, such as bottom welding And pipe welding; argon tungsten arc welding is also suitable for thin plate welding.

Post time: Feb-15-2023