News

-

Lathes are classified by use and function

Lathes are divided into various types according to their purpose and function: The ordinary lathe has a wide range of processing objects, and the adjustment range of the spindle speed and feed is large, and it can process the inner and outer surfaces, end faces and internal and external threads ...Read more -

Features of stamping process

Stamping parts are mainly formed by stamping metal or non-metal sheet materials with the help of the pressure of the press through the stamping die. It mainly has the following characteristics: ⑴ Stamping parts are made by stamping under the premise of low material consumption. The parts are ligh...Read more -

The difference between strong spin and normal spin

Spinning can be divided into ordinary spinning and strong spinning according to the deformation characteristics of metals. Although they are a kind of processing technology at the same time, but there are certain differences in the technique and the effect of processing. The following provides t...Read more -

What is casting production

Casting production is a complex thermoforming process, and the production of a casting is limited in many ways. Usually, a suitable production method is determined according to the structural complexity, quantity, precision requirements, material, size, processing, surface treatment requirements,...Read more -

Electric Discharge Machining

The method of dimensional processing of materials by using the corrosion phenomenon produced by spark discharge is called EDM. CNC EDM is a computer digitally controlled EDM, which realizes multi-axis linkage machining. CNC EDM realizes automatic control through computer to complete complex and ...Read more -

Introduction to Gravity Casting

Permanent mold #casting refers to a process in which molten metal is injected into a mold under the action of the earth’s gravity, also known as gravity casting. The generalized gravity #casting includes sand casting, metal casting, investment casting, lost foam #casting, mud casting, etc.;...Read more -

Application of shell molding and resin sand molding

Shell molding . Sand or core sand with a layer of solid resin film on the surface of the sand before molding. There are two coating processes: cold method and hot method: the cold method dissolves the resin, and urotropine is added during the sand mixing process, so that the two are coated on the...Read more -

The difference between high pressure casting and low pressure casting

The difference between high pressure casting and low pressure casting. 1. The essence of high-pressure casting (referred to as die-casting) is to make liquid or semi-liquid metal fill the cavity of the #die-casting mold (die-casting mold) at a high speed under the action of high pressure, and for...Read more -

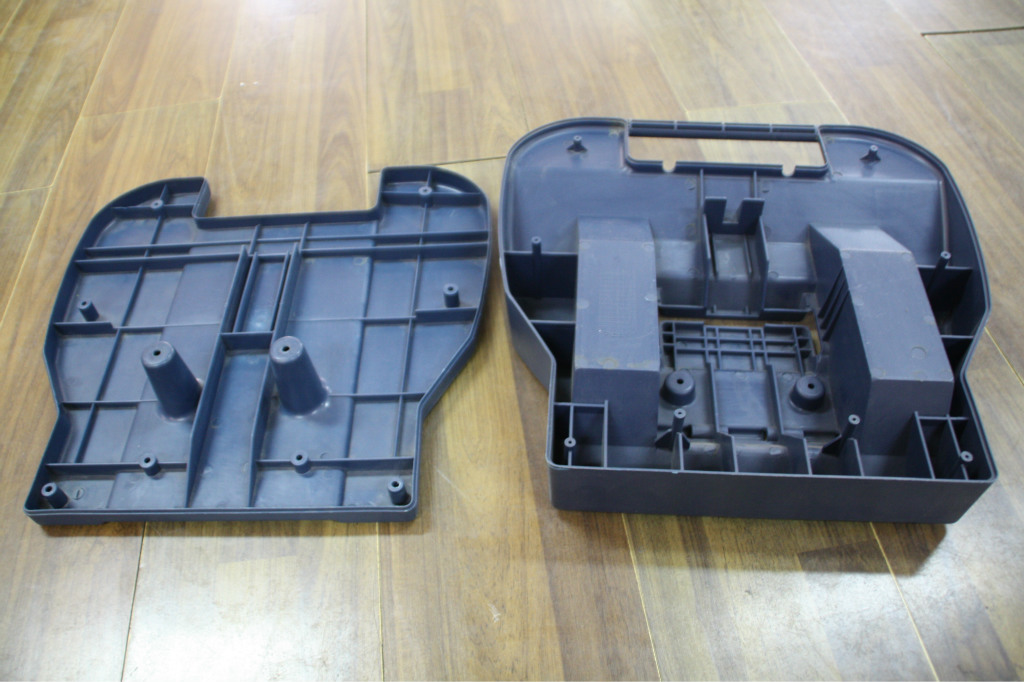

Plastic injection moulding

Plastic injection mould are mainly in the production of thermoplastic plastic products has been widely applied in the kind of forming dies, plastic injection mold and the corresponding equipment is plastic injection molding machine, plastic in the first place in the bottom of the injection machin...Read more -

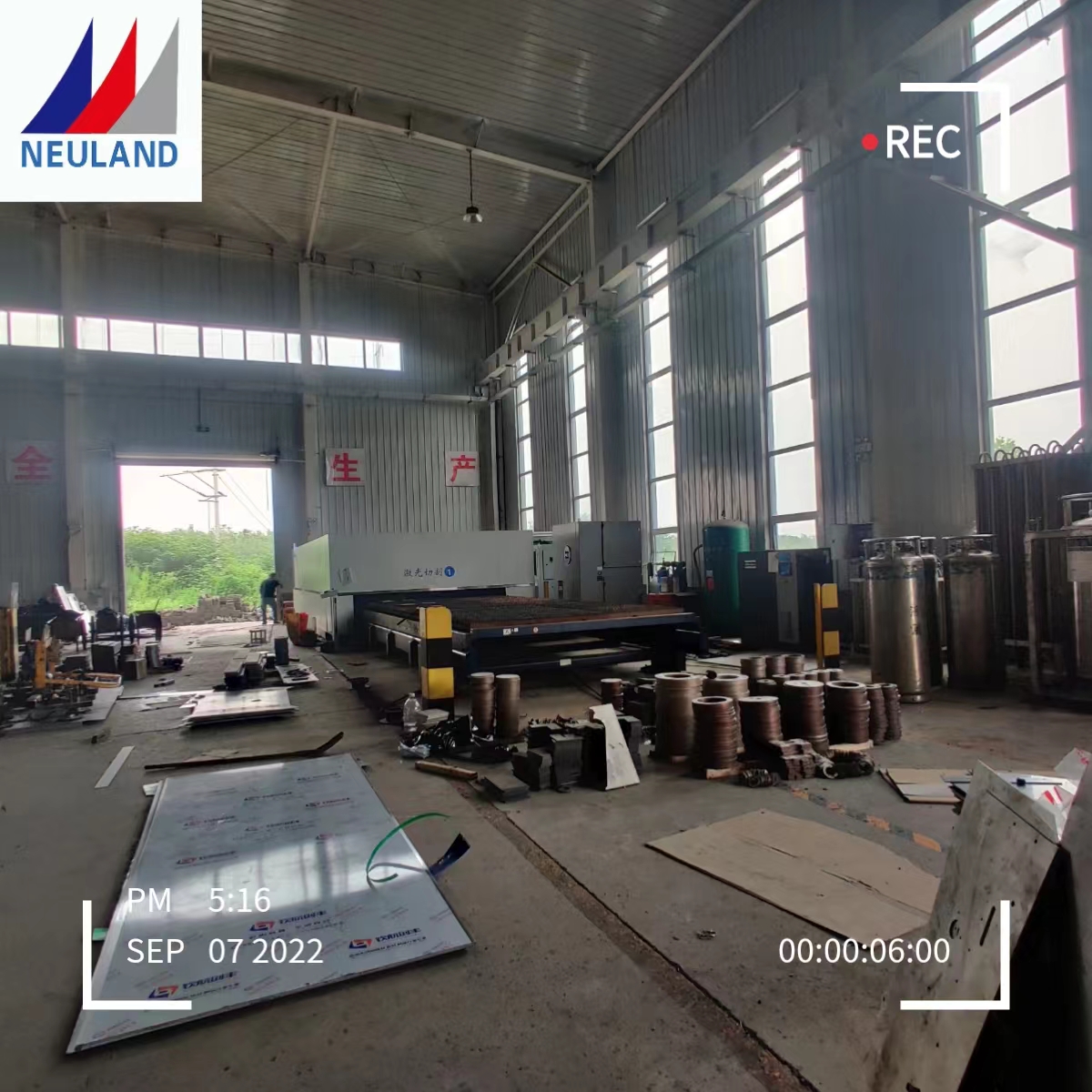

Laser Cutting

Laser cutting uses a high power density laser beam to irradiate the material to be cut, so that the material is quickly heated to the vaporization temperature and evaporated to form holes. As the beam moves to the material, the holes continuously form a narrow width (such as about 0.1mm). Cut the...Read more -

Classification of casting

There are mainly two types of sand casting and special casting. 1 Ordinary sand casting, which uses sand as a mold material, also known as sand #casting and sand casting, includes three types of wet sand, dry sand and chemically hardened sand, but not all sands can be used for casting. The advant...Read more -

Welding process and application

Welding is a process and connection method that produces atomic bonding between two workpieces of the same sex or opposite sex by heating, pressurizing, or using both. Welding has a wide range of applications, both for metals and for non-metals. Welding technology is mainly used on metal base mat...Read more