News

-

Milling Machines and Milling Cutters

There are many shapes of milling cutters, which are used for processing slots and linear contours on ordinary milling machines and CNC milling machines, and for machining cavities, cores, and curved surface shapes/contours on milling and boring machining centers. Generally divided into: 1. Flat e...Read more -

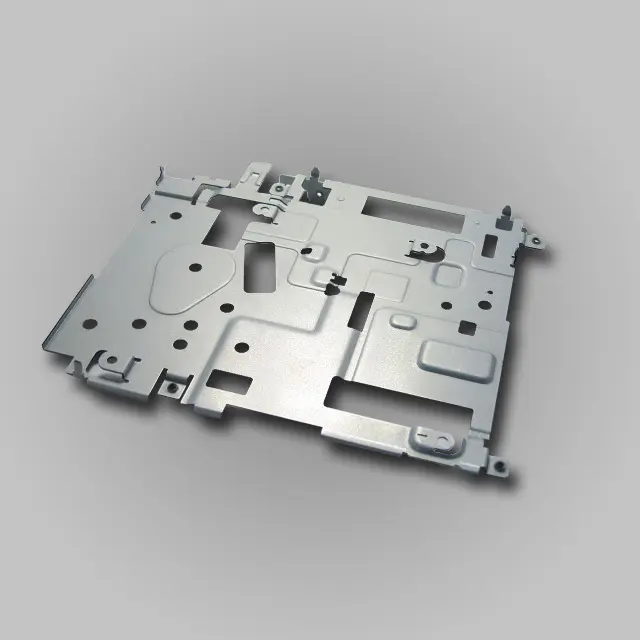

About Stamping

Sheet metal stamping is also known as “stamping”. This is a process that uses a lot of force to change the shape of a flat sheet of metal. The process may also involve punching holes in the metal. Sheet metal stamping is a very common process. In fact, sheet metal stamping is part of ...Read more -

The difference between TIG and Laser welding

1. Different technical principles 1. Laser welding: Laser radiation heats the surface to be processed, and the surface heat diffuses to the inside through heat conduction. By controlling laser parameters such as laser pulse width, energy, peak power and repetition frequency, the workpiece is melt...Read more -

MIG-Welding

Carbon dioxide shielded welding full name carbon dioxide gas shielded arc welding. The protective gas is carbon dioxide (sometimes CO2+Ar mixture), mainly used for hand welding. Due to the special influence of the thermal and physical properties of carbon dioxide gas, when using conventional weld...Read more -

Welding Process

Welding, is a manufacturing process and technology that uses heat, high temperature, or pressure to join metal or other thermoplastic materials such as plastics. There are many sources of energy for modern welding, including gas flames, electric arcs, lasers, electron beams, friction, and ultraso...Read more -

Vertical self-rotating wire EDM

Vertical self-rotating #wire EDM (horizontal self-rotating wire EDM). The characteristics of the vertical rotary WEDM machine are different from the traditional high-speed WEDM and low-speed WEDM. First, the movement of the electrode wire is one more electrode than the traditional two kinds of WE...Read more -

Characteristics of die-casting die

The die-casting mold is composed of two parts, namely the covering part and the moving part. The combined part is called the parting line. In hot chamber die casting, the covering part has a gate, while in cold chamber die casting, it is an injection port. Molten metal can enter the mold from her...Read more -

What is laser cutting

Laser cutting is the use of a focused high-power-density laser beam to irradiate the workpiece, so that the irradiated material is rapidly melted, vaporized, ablated or reached the ignition point, and at the same time the molten material is blown away by the high-speed airflow coaxial with the be...Read more -

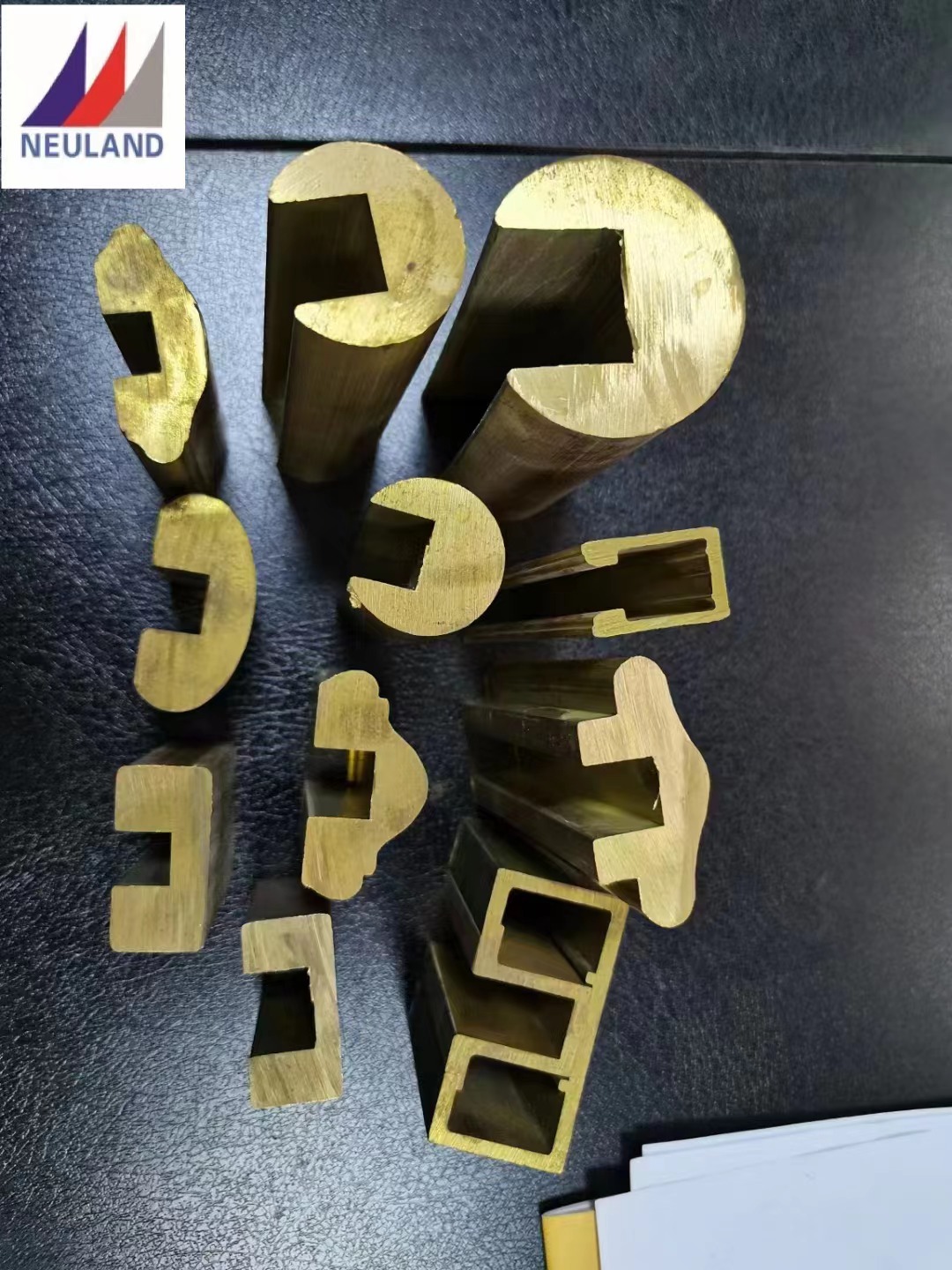

About the COPPER

Copper is one of the earliest ancient metals discovered by human beings. As early as three thousand years ago, humans began to use copper. Copper in nature is divided into natural copper, copper oxide and copper sulfide. The reserves of natural copper and copper oxide are small. Now more than 80%...Read more -

What can a four axis CNC machining center do?

After the fourth axis is added to the NC machining center machine tool, it is usually called a four axis NC machining center. It can complete tasks that the three-axis machine tool cannot complete at one time. It realizes the multi-faceted processing of the processed products through the rotation...Read more -

What is anodizing

The so-called anodizing of aluminum is an electrolytic oxidation process in which the surface of aluminum and aluminum alloys is usually converted into an oxide film, which has protective, decorative and some other functional properties. The anodic oxidation of #aluminum starting from this defini...Read more -

Brass insert in plastic moulding

Injection molded copper nuts can also be understood as inlaid copper nuts or embedded copper nuts. Different injection molded copper nuts have appeared in the market today, and their uses are also different. The main purpose of the copper insert is to inject the product into some plastic parts, a...Read more