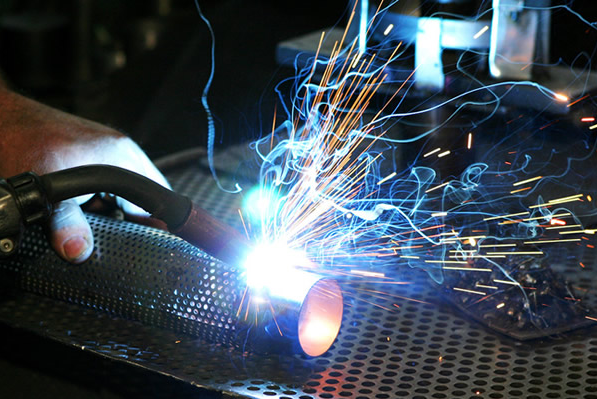

Welding, is a manufacturing process and technology that uses heat, high temperature, or pressure to join metal or other thermoplastic materials such as plastics.

There are many sources of energy for modern welding, including gas flames, electric arcs, lasers, electron beams, friction, and ultrasound. In addition to its use in factories, welding can also be performed in a variety of environments, such as in the field, underwater and in space. Welding, wherever it occurs, can pose a hazard to the operator, so proper precautions must be taken when welding. Possible injuries caused by welding to the human body include burns, electric shock, visual impairment, inhalation of toxic gases, and excessive ultraviolet radiation.

Welding achieves the purpose of joining through the following three ways:

1. Fusion welding – heating the workpieces to be joined to make them partially melt to form a molten pool, and then join after the molten pool is cooled and solidified. If necessary, fillers can be added to assist. It is suitable for welding processing of various metals and alloys. pressure.

2. Pressure welding – the welding process must exert pressure on the weldment, which belongs to the processing of various metal materials and some metal materials.

3. Brazing—Using a metal material with a lower melting point than the base metal as the solder, using liquid solder to wet the base metal, filling the joint gap, and interdiffusion with the base metal to realize the joint weldment. It is suitable for welding processing of various materials, and also suitable for welding processing of different metals or heterogeneous materials.

Post time: Feb-08-2023