New Fashion Design for China Investment Casting Supplier - Iron casting – Neuland Metals

New Fashion Design for China Investment Casting Supplier - Iron casting – Neuland Metals Detail:

Iron casting normally produced through sand casting process. Sand casting as a technology has been selected as a preferred method to produce shaped parts that weigh from less than a pound to very large parts. The process is versatile and cost effective, even for low volume runs because of tooling cost. Nearly any part configuration that can be made using another casting process can be reduced to a pattern and created as a sand casting. Cast iron is a ferrous alloy of iron, carbon and silicon. With carbon content of 2.1 to 4.5 % and silicon at about 2.2% and small amount of Sulphur, Manganese and Phosphorous.

Iron casting is one of the oldest casting methods in the world. The cast iron is molten and poured into molds or casts to make a part of products of desired size and shape. The cast iron can be used in a wide range of industries. In the manufacturing process of Cast Iron, the alloying elements determine cast iron type. Compared with steel casting, iron casting has a wider range of advantages of its properties. The cast iron main types are Grey, Ductile, Compacted graphite, White, Malleable, Abrasion resistant and Austenitic.

Typical Applications for Iron Castings:

– Engineering Castings

– Heavy Engineering Plant & Equipment

– Original Equipment Manufacturers

– Petrochemical & Oil Production Sector

– Aerospace Applications

– Shipping Construction

– Transportation Infrastructure & Railway Stock

– Mining, Quarrying & Minerals

– Energy Sector & Power Production

– Hydro Applications

– Pump & Valve Manufacturers

– Rolling Mills & Steel Production

– Special Engineering Cast Iron Castings

– Architectural Castings

– Decorative Castings

The most popular molding methods for casting iron part are green sand molding, shell molding, resin sand molding and lost foam method.

With the great development in the past years, all our production is fairly automatic with molding lines such as vertical or horizontal molding lines, automatic pouring machine are introduced.

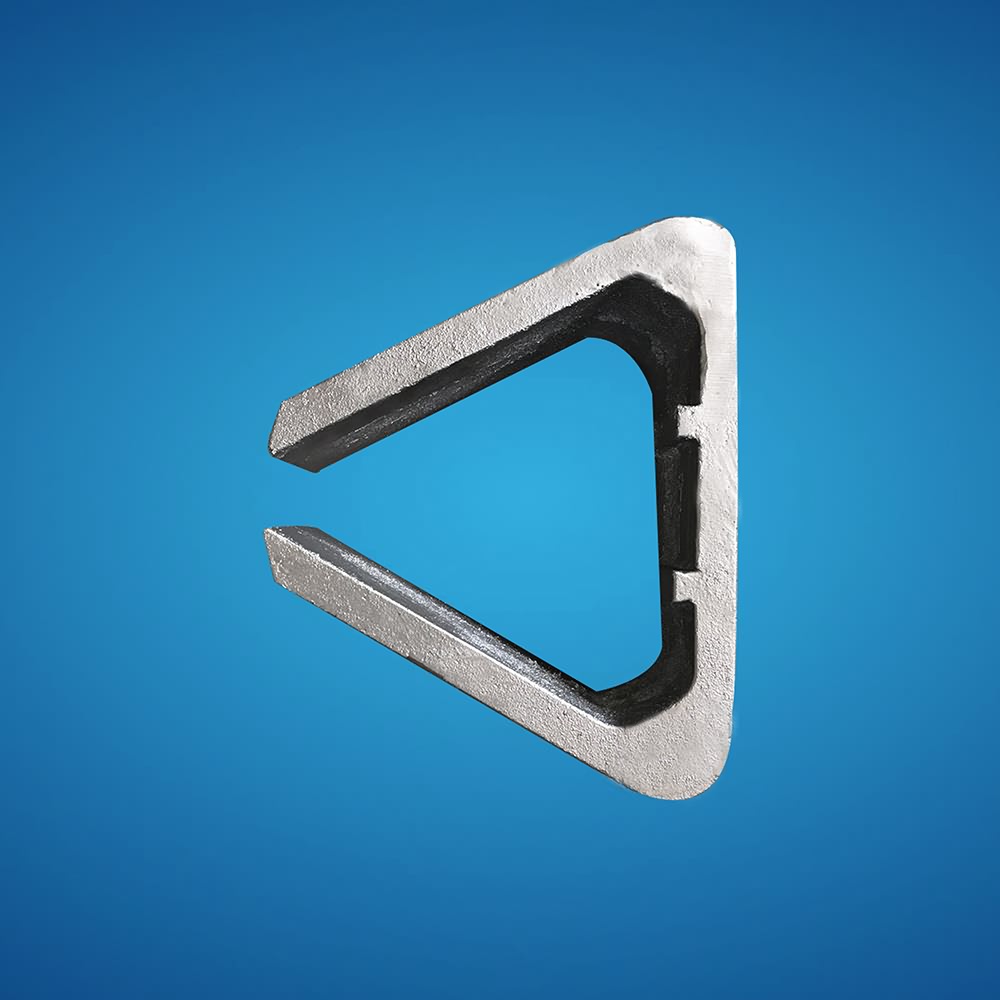

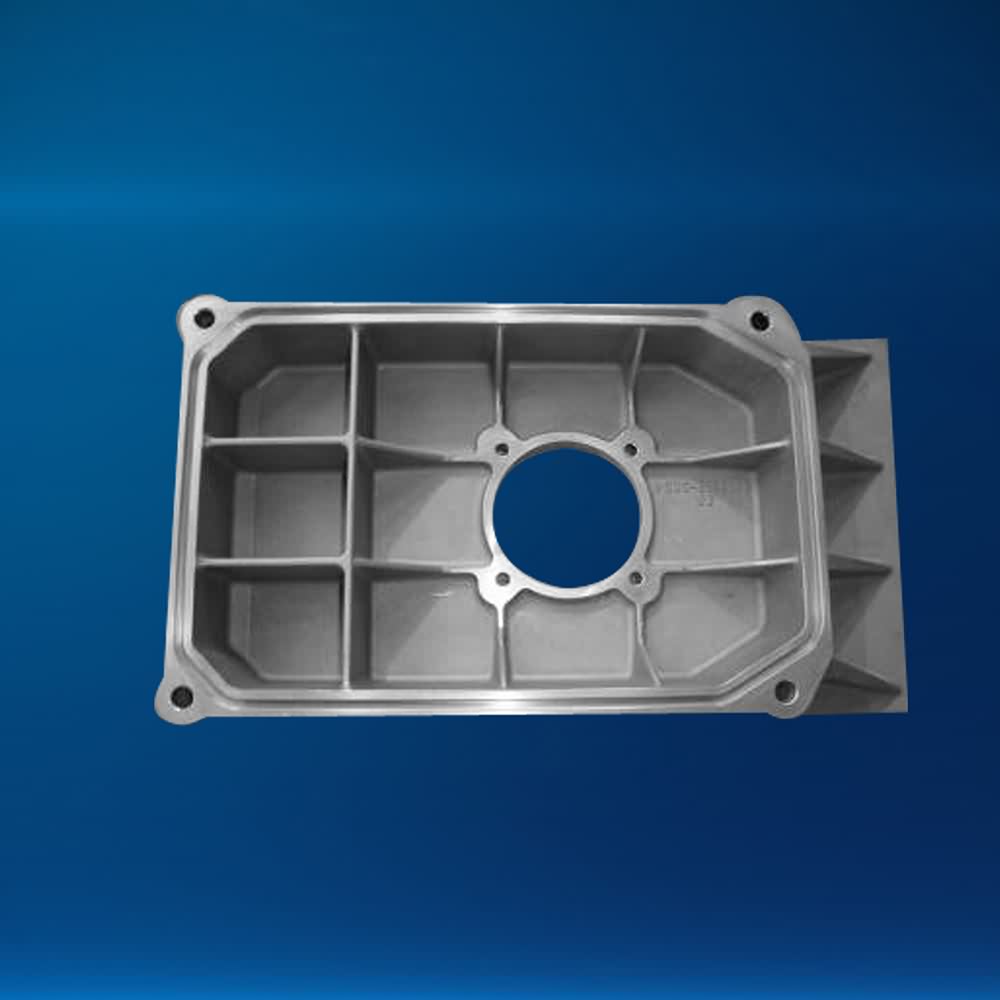

Product detail pictures:

Related Product Guide:

Our development depends on the advanced equipment ,excellent talents and continuously strengthened technology forces for New Fashion Design for China Investment Casting Supplier - Iron casting – Neuland Metals , The product will supply to all over the world, such as: Cairo, Oslo, Barcelona, Based on products and solutions with high quality, competitive price, and our full range service, we have accumulated experienced strength and experience, and we've built up a very good reputation in the field. Along with the continuous development, we commit ourselves not only to the Chinese domestic business but also the international market. May you moved by our high quality items and passionate service. Let's open a new chapter of mutual benefit and double win.

The factory workers have rich industry knowledge and operational experience, we learned a lot in working with them,we are extremely grateful that we can encount a good company has excellent wokers.