Steel Forging Parts - Factory, Suppliers, Manufacturers from China

Assume full duty to satisfy all demands of our clients; reach steady advancements by marketing the development of our purchasers; grow to be the final permanent cooperative partner of clientele and maximize the interests of customers for Steel Forging Parts, Gravity Cast, Machining Parts Supplier, Steel Casting,Bronze Cast Manufacturer. As a leading manufacture and exporter, we appreciate a great status inside the international markets, especially in America and Europe, because of our top high-quality and sensible charges. The product will supply to all over the world, such as Europe, America, Australia,Bangladesh, Boston,Belgium, Tunisia.Since its foundation , the company keeps living up to the belief of "honest selling , best quality , people-orientation and benefits to customers. " We're doing everything to supply our customers with best services and best solutions . We promise that we are going to be responsible all the way to the end once our services begin.

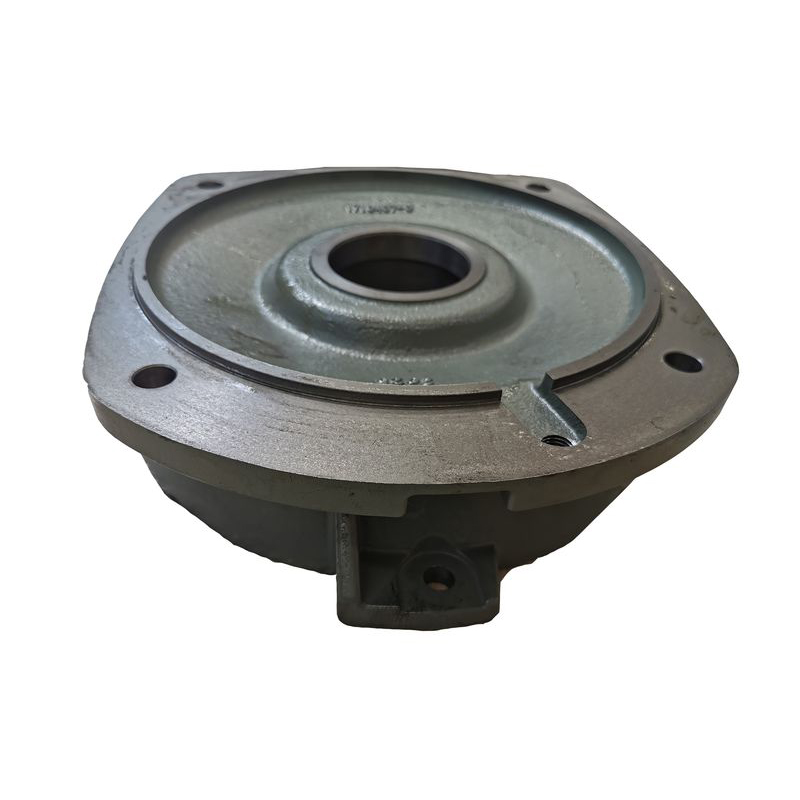

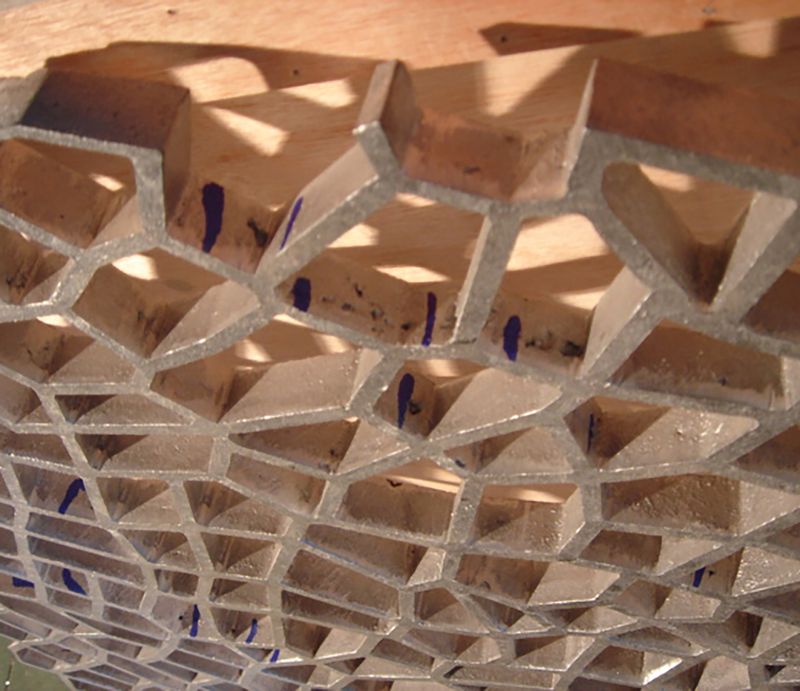

Related Products