Cast Ductile Iron - China Factory, Suppliers, Manufacturers

Our firm aims to operating faithfully, serving to all of our shoppers , and working in new technology and new machine regularly for Cast Ductile Iron, Precision Aluminum Extrusion, Customized Brass Casting, Custom Cast Steel,Forged Aluminum. We warmly welcome business partners from all walks of life, expect to establish friendly and cooperative business contact with you and achieve a win-win goal. The product will supply to all over the world, such as Europe, America, Australia,Rotterdam, America,Panama, France.We are in continuous service to our growing local and international clients. We aim to be worldwide leader in this industry and with this mind; it is our great pleasure to serve and bringing the highest satisfaction rates among the growing market.

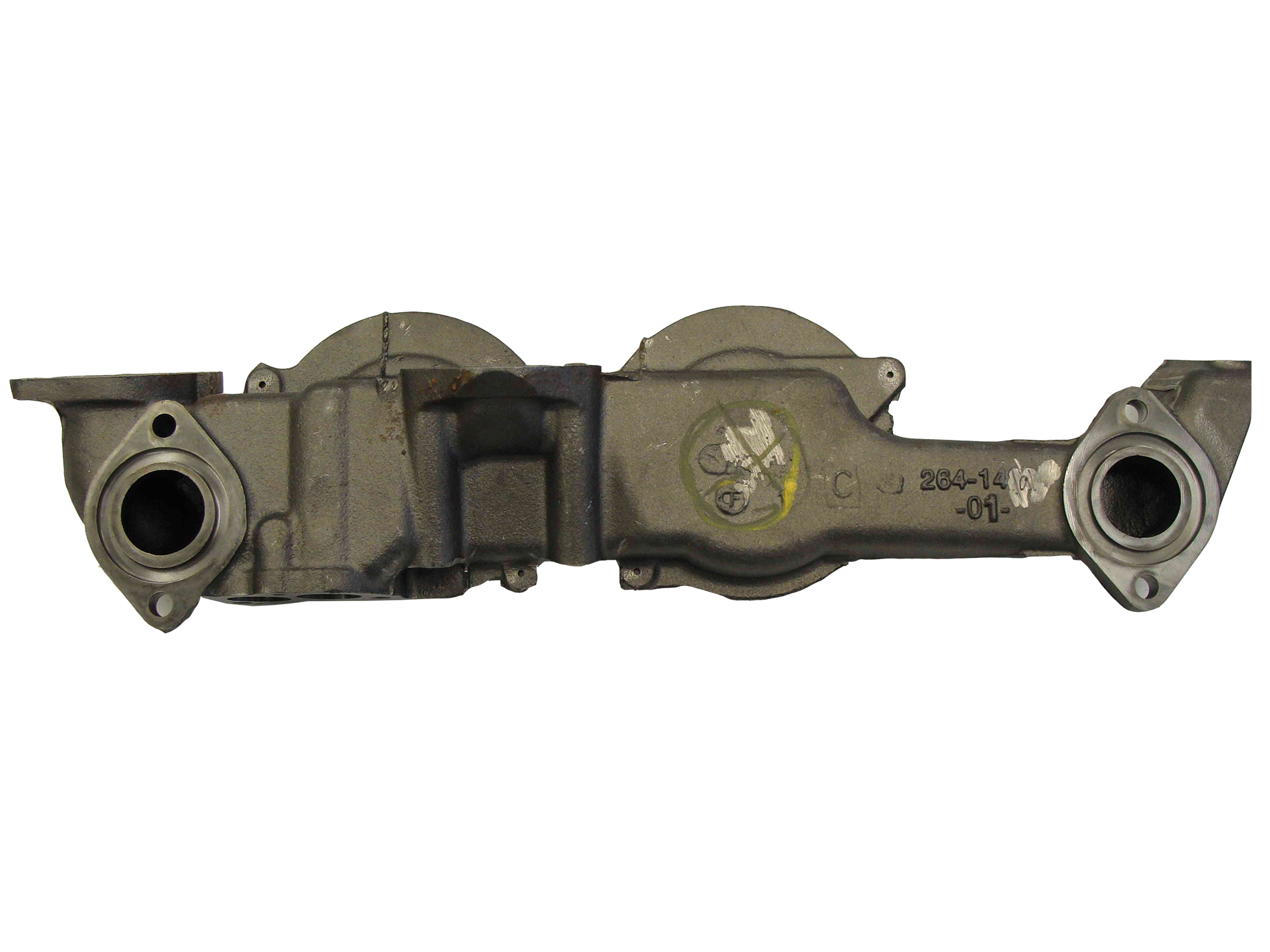

Related Products