Customized Steel Casting - China Manufacturers, Suppliers, Factory

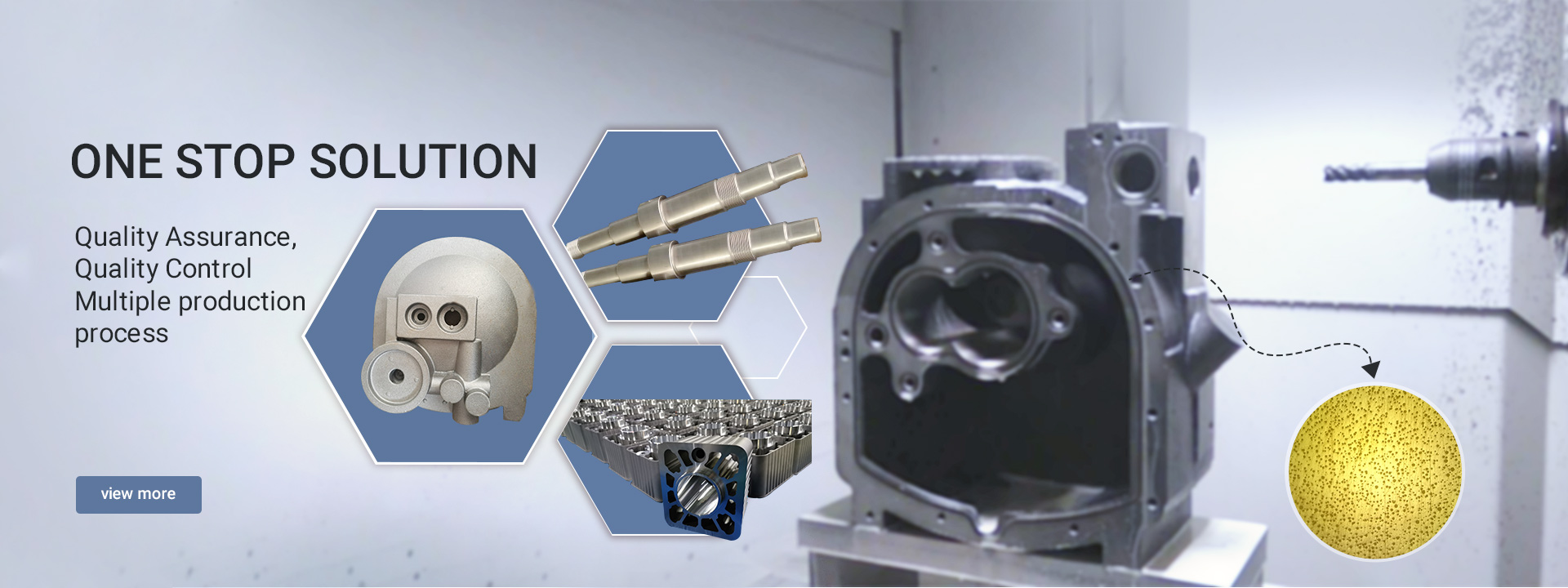

Good quality comes 1st; assistance is foremost; business enterprise is cooperation" is our business enterprise philosophy which is regularly observed and pursued by our company for Customized Steel Casting, Precision Turned Product Manufacturer, Aluminum Precision Milling Parts, Cast Ductile Iron,Gravity Die Cast. For even more inquires remember to do not hesitate to get in touch with us. Thank you - Your support continuously inspires us. The product will supply to all over the world, such as Europe, America, Australia,Hanover, Belize,Mauritania, Chile.With the best technological support, we have tailored our website for the best user experience and kept in mind your ease of shopping. we ensure that the best reaches you at your doorstep, in the shortest possible time and with the help of our efficient logistical partners i.e DHL and UPS. We promise quality, living by the motto of promising only what we can deliver.

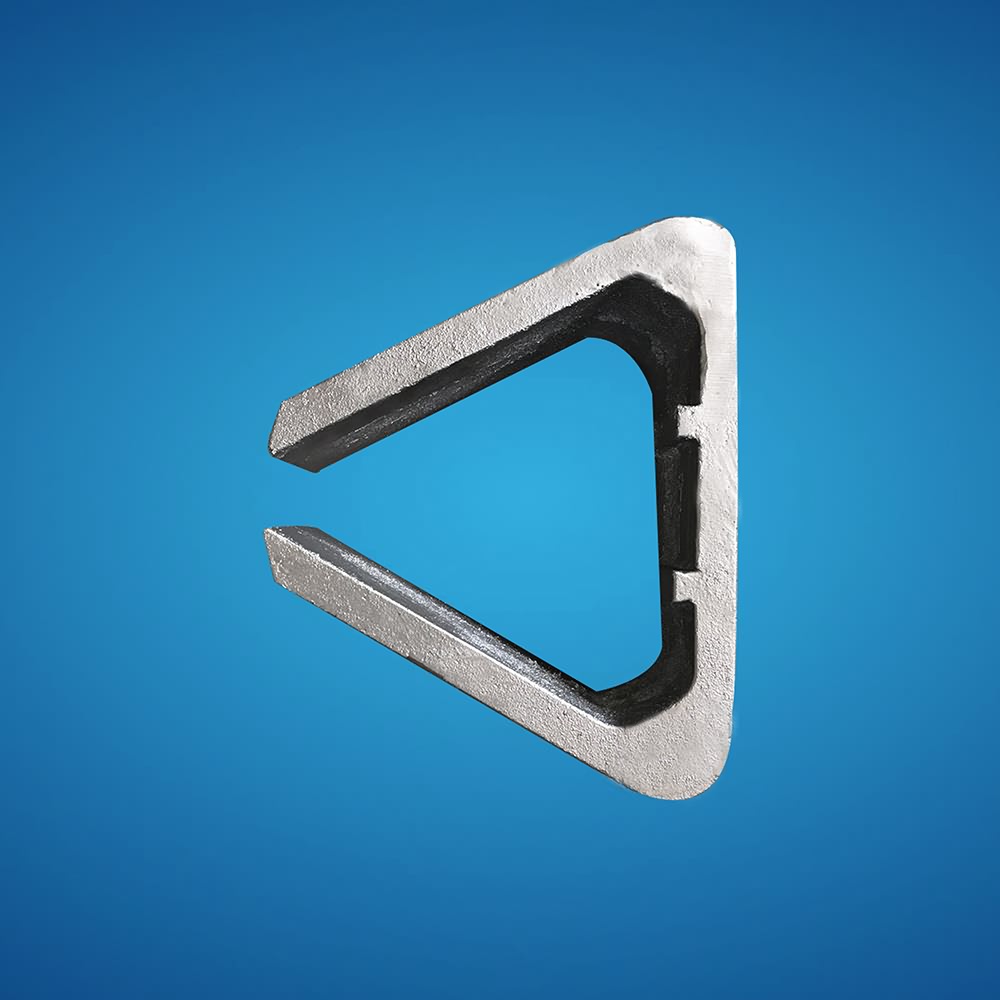

Related Products