Discount Price Custom Brass Cast - Forging parts – Neuland Metals

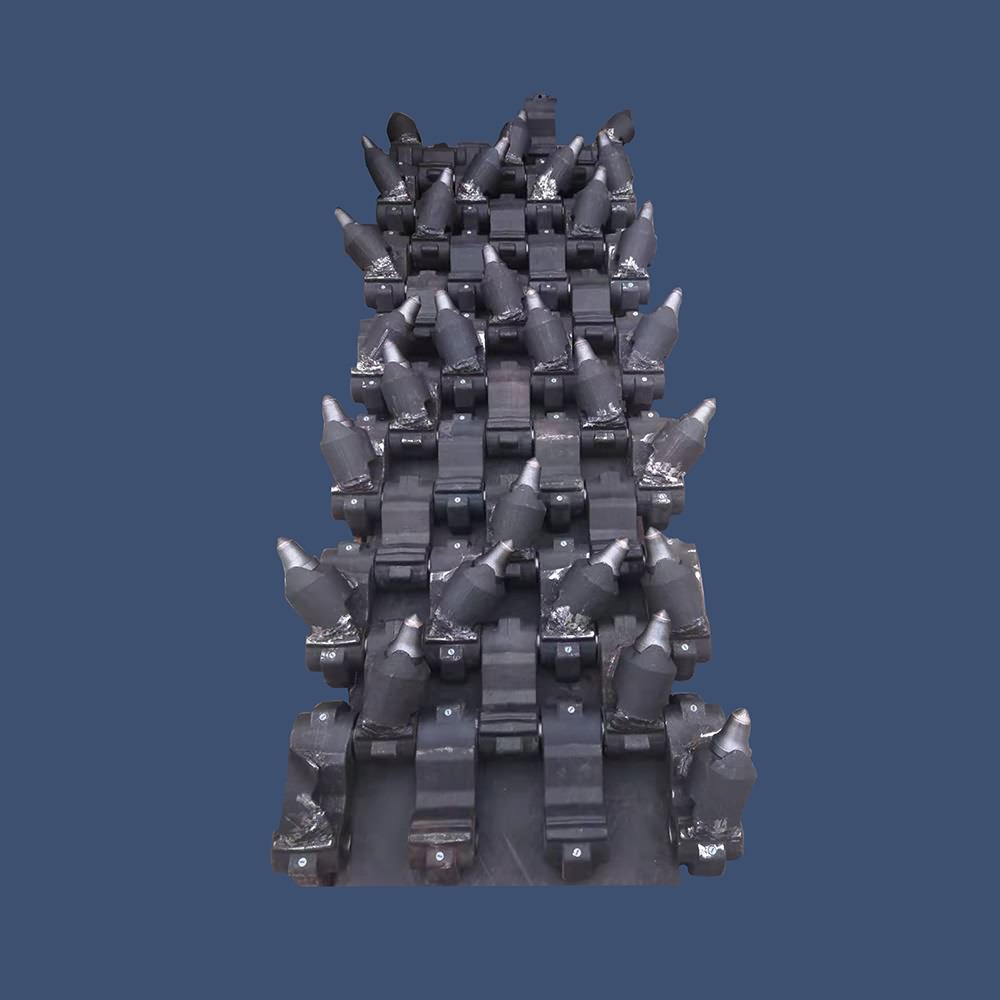

Discount Price Custom Brass Cast - Forging parts – Neuland Metals Detail:

Material: carbon, alloy and stainless steels; very hard tool steels; aluminum; brass and copper; and high-temperature alloys

Processing: Die forging or free forging

Weight:1-1000KG

Processing capacity: Diameter 10mm-6000mm

Forging is manufacturing process where metal is pressed, pounded or squeezed under great pressure into high strength parts known as forgings. The process is normally (but not always) performed hot by preheating the metal to a desired temperature before it is worked. It is important to note that the forging process is entirely different from the casting (or foundry) process, as metal used to make forged parts is never melted and poured (as in the casting process).

The forging process can create parts that are stronger than those manufactured by any other metalworking process. This is why forgings are almost always used where reliability and human safety are critical. But forging parts can rarely be seen because normally the parts are assembled inside of machinery or equipment, like ships, oil drilling facilities, engines, automobiles, tractors, etc.

The most common metals that can be forged include: carbon, alloy and stainless steels; very hard tool steels; aluminum; titanium; brass and copper; and high-temperature alloys which contain cobalt, nickel or molybdenum. Each metal has distinct strength or weight characteristics that best apply to specific parts as determined by the customer.

Forging is categorized into hot forging, warm forging and cold forging in terms of temperature.

While according to its forming procedures, forging can also be classified as free forging, die forging, and special forging.

Forging parts are widely used in industries like air plane, diesel engine, ships, military, mining industry, nuclear power, oil&gas, chemical, etc.

Product detail pictures:

Related Product Guide:

We also present product or service sourcing and flight consolidation products and services. We have our possess manufacturing facility and sourcing place of work. We can easily supply you with almost every type of product or service connected to our item variety for Discount Price Custom Brass Cast - Forging parts – Neuland Metals , The product will supply to all over the world, such as: Washington, Bandung, Houston, At Present, our products have been exported to more than sixty countries and different regions, such as Southeast Asia, America, Africa, Eastern Europe, Russia, Canada etc. We sincerely hope to establish wide contact with all potential customers both in China and the rest part of the world.

After the signing of the contract, we received satisfactory goods in a short term, this is a commendable manufacturer.