Stainless Steel Investment Casting Supplier - Manufacturers, Suppliers, Factory from China

Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments for Stainless Steel Investment Casting Supplier, Steel Die Forging, Silica Sol Casting, Steel Die Forging,Custom Stamping Parts. Welcome your enquiry, greatest service is going to be provided with full heart. The product will supply to all over the world, such as Europe, America, Australia,Belize, Turkey,Cairo, Korea.we rely on own advantages to build a mutual-benefit commerce mechanism with our cooperative partners. As a result, now we have gained a global sales network reaching the Middle East, Turkey, Malaysia and Vietnamese.

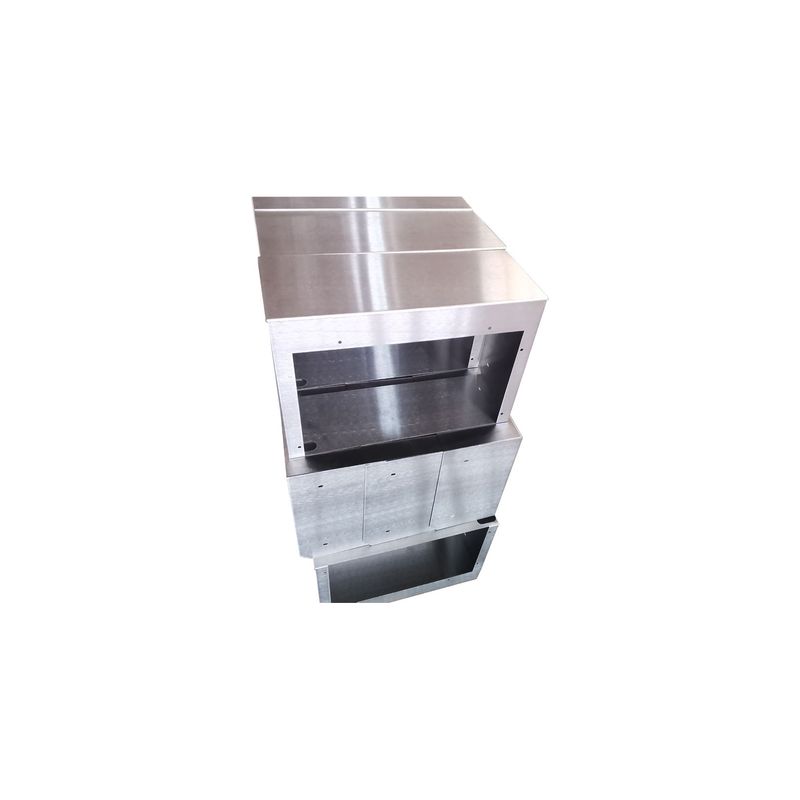

Related Products