Custom Stainless Steel Products - China Manufacturers, Suppliers, Factory

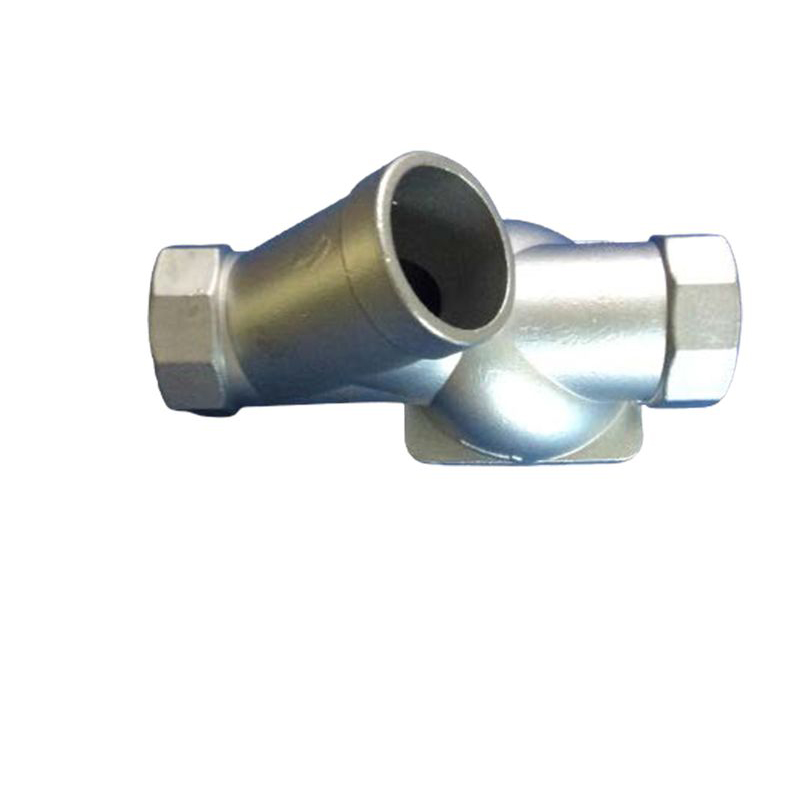

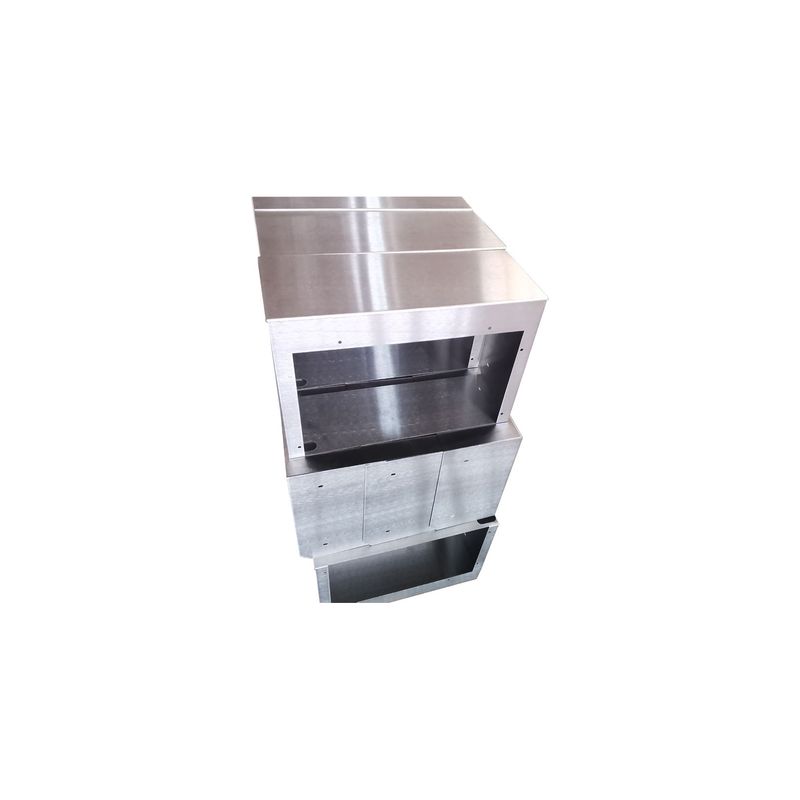

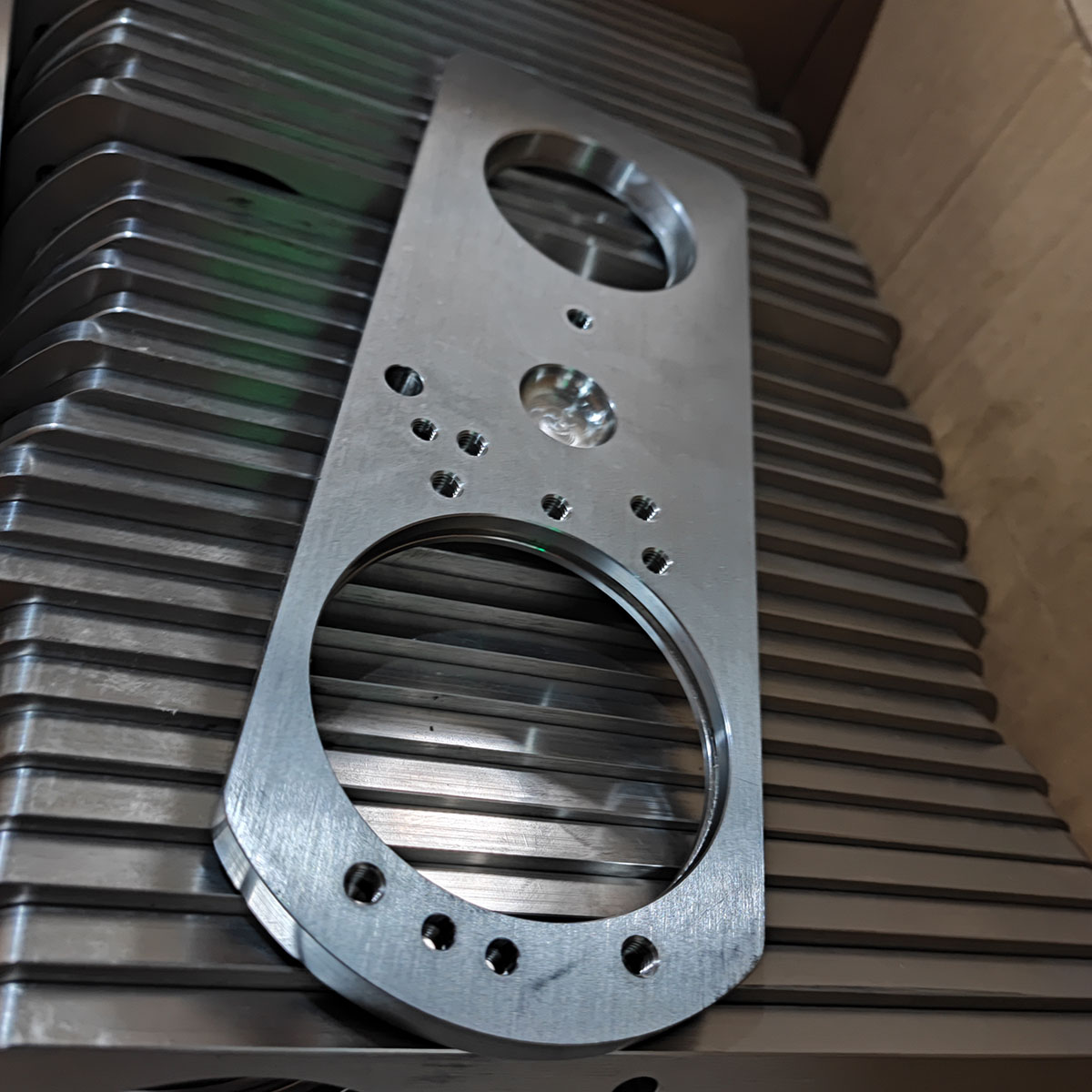

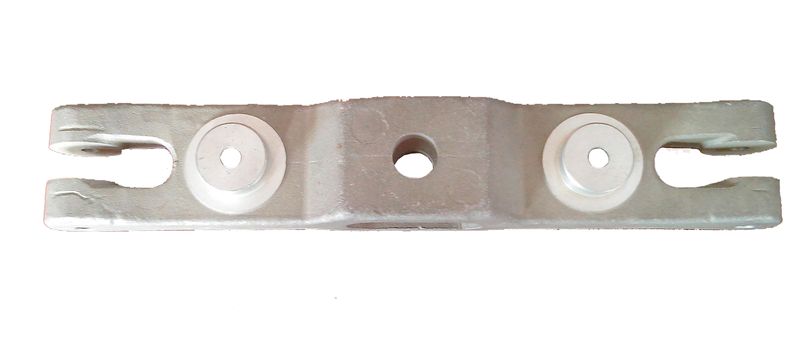

We take pleasure in an exceptionally excellent status between our buyers for our superb merchandise good quality, aggressive price tag and the greatest support for Custom Stainless Steel Products, Stamping, Custom Cnc C Milling Parts, Die Casting,Metal Stamping Manufacturer. Our intention is to assist clients understand their ambitions. We are earning wonderful attempts to realize this win-win predicament and sincerely welcome you to be a part of us. The product will supply to all over the world, such as Europe, America, Australia,Philippines, Korea,Slovakia, Greece.Abiding by our motto of "Hold well the quality and services, Customers Satisfaction", So we provide our clients with high quality products and excellent service. Please feel free to contact us for further information.

Related Products