News

-

Precision casting

Precision casting can also be divided into gravity casting and pressure casting according to the pouring process of molten metal. Gravity casting refers to the process of pouring molten metal into a mold under the action of the earth’s gravity, also known as casting. Gravity casting include...Read more -

Water glass precision casting

The process of sodium silicate shell has been produced for nearly 50 years in China. Through the unremitting efforts of colleagues in the investment casting industry for half a century, the application and research of sodium silicate shell process have reached a very high level. Over the years, t...Read more -

Bending Process

Bending is a stamping process that uses pressure to force a material to plastically deform to form a shape with a certain angle and curvature. Bending is one of the most common sheet metal fabrication operations. Also known as press bending, flanging, die bending, folding and trimming, this metho...Read more -

The stamping process can be divided into two categories?

Stamping and forming The stamping process can be divided into two categories: separation process and forming process. Separation process: The separation process refers to the process of separating the blank along a certain contour line to obtain a stamping part of a certain shape, size and cross-...Read more -

What is the difference between sheet metal processing and stamping processing?

First of all, conceptually, sheet metal processing refers to the processing of metal sheets, which is to use sheets to make common items in our daily life, such as chimneys, iron barrels, oil tanks, ventilation ducts, elbows, and rounded places. , funnel-shaped, etc., it is mainly made by cutting...Read more -

Powder Coating Process

Powder coating is the use of electrostatic spraying machine to spray powder coating on the surface of the workpiece. Under the action of static electricity, the powder will be uniformly adsorbed on the surface of the workpiece to form a powder coating. At present, there are four main types: arc s...Read more -

Different types of welding characteristics and processing methods

There are more than 40 kinds of metal welding methods, mainly divided into three categories: fusion welding, pressure welding and brazing. fusion #welding Fusion welding is a method in which the workpiece interface is heated to a molten state during the welding process, and the welding is complet...Read more -

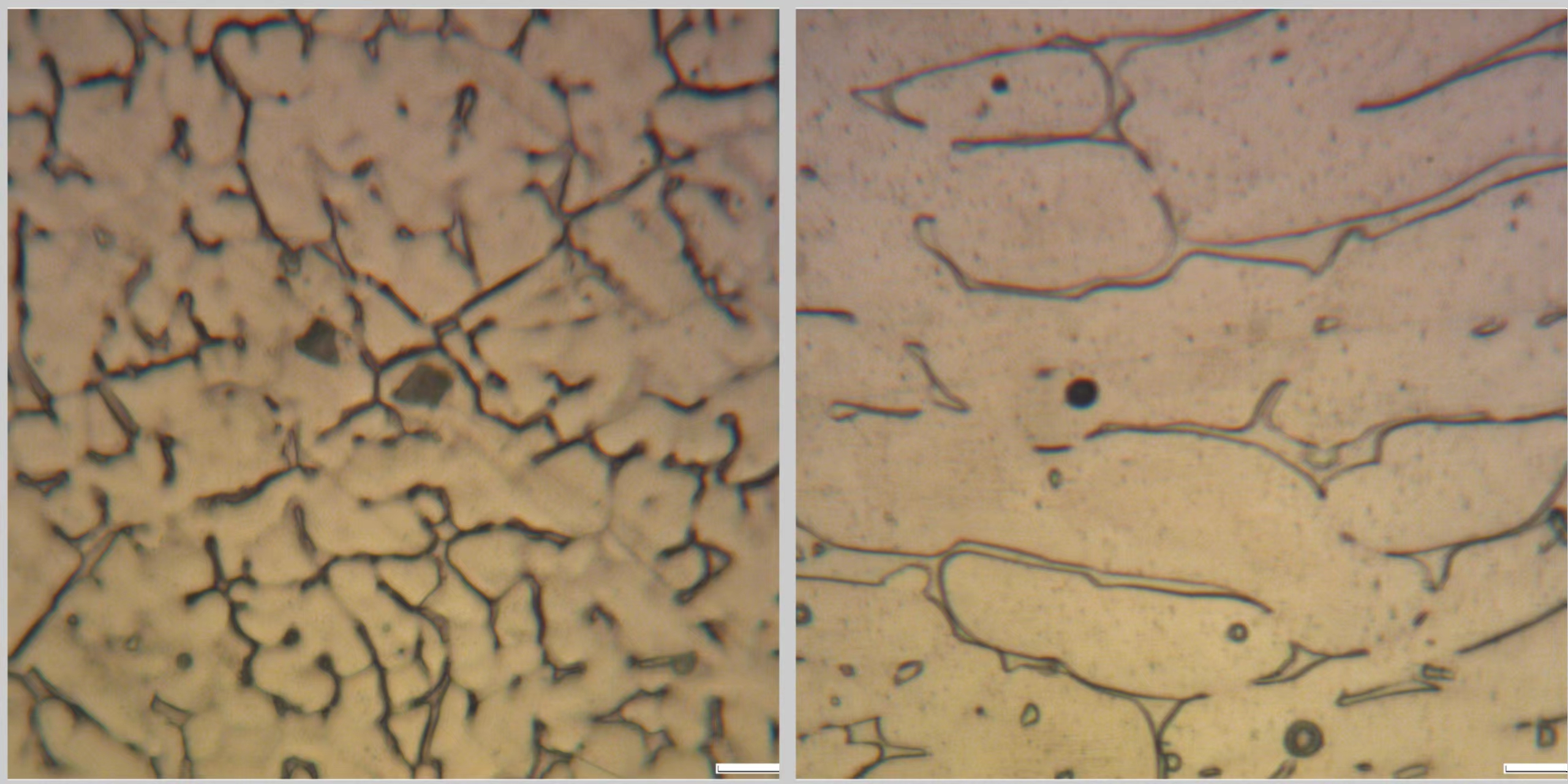

Details of cooling operations in the investment casting process

The application range of precision castings is getting wider and wider, and there are more and more processing techniques. Among them, the cooling process is an essential process, and some also undergo the solid phase transformation of the alloy. During this process, the contrast of metals change...Read more -

Solution treatment of 304 stainless steel castings

Solid solution treatment refers to the process of heating the alloy to the temperature at which the second phase can be completely or maximally dissolved into the solid solution, and then keeping it for a period of time, cooling it faster than the second phase precipitates from the solid solution...Read more -

The working principle of horizontal machining center

The spindle of a horizontal machining center is horizontal, usually with a square table for indexing rotary motion. Generally, there are 3 to 5 motion coordinates. The common one is three linear motion coordinates plus one rotary motion coordinate. It can make the workpiece complete the processin...Read more -

Salient Features of Horizontal Machining Centers

The horizontal machining center is widely used in the processing of box parts, shell parts, disc parts, and special parts in the automotive, mold, machinery manufacturing and other industries. The parts can automatically complete four-sided milling, boring, Drilling, expanding, reaming, tapping a...Read more -

How are the parts manufactured?

Machining (machining) simply means that the material is processed by mechanical equipment, such as cutting the material by cutting, so as to process the desired workpiece shape. According to the drawings and dimensions of the drawings, the whole process of making the shape, size, relative positio...Read more