News

-

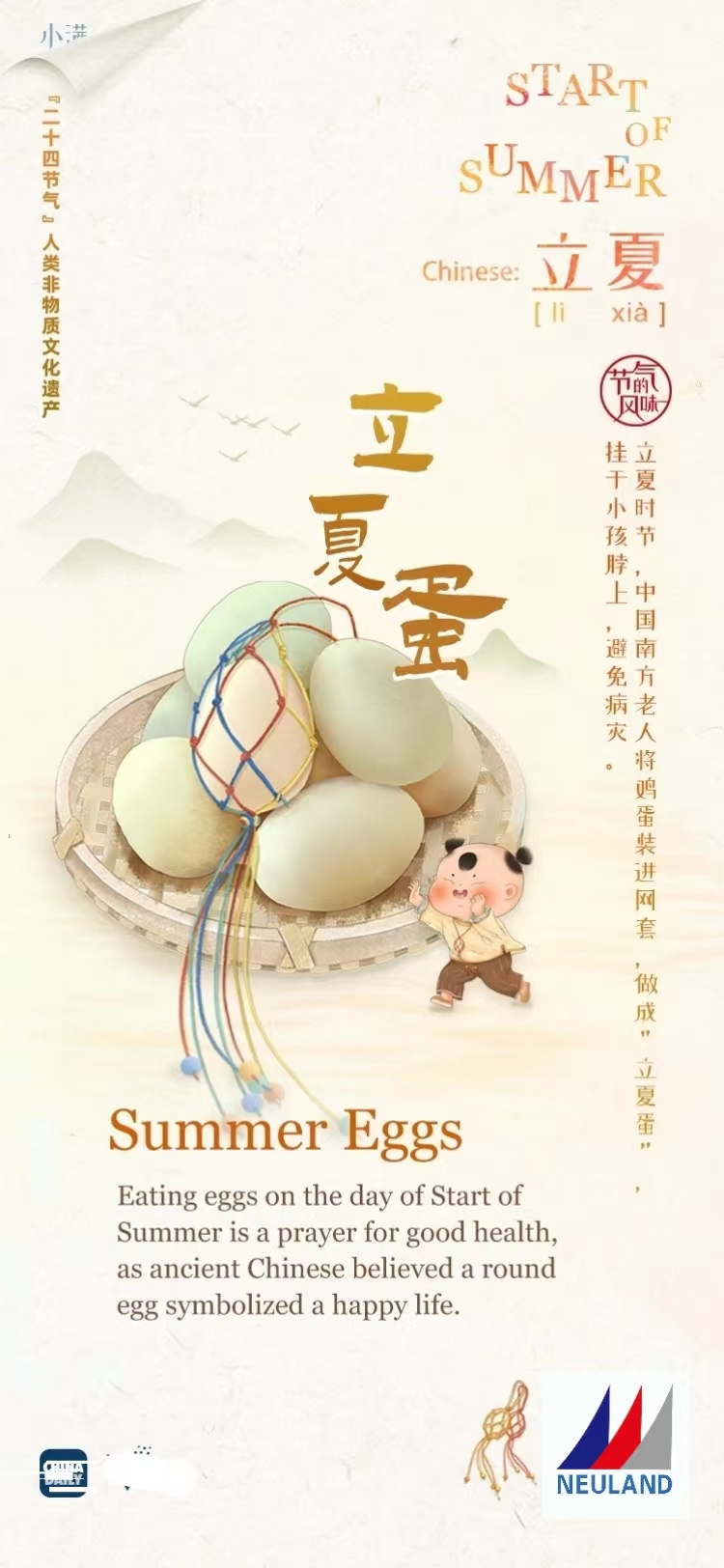

Lixia’s Story-Summer Eggs

As the sun rises on a clear day in early May, millions of Chinese celebrate the start of summer, a traditional festival dating back more than 2,500 years. The holiday is called “Lixia” in Mandarin, and it is considered one of the twenty-four solar terms in the Chinese calendar. Lixia&...Read more -

China Aerospace Day – Development of New Materials in China’s Aerospace Field

(1) Development trend of titanium and titanium alloy materials Titanium alloy has become the most ideal structural material in the aviation industry because of its excellent performance characteristics. Judging from the development trend of materials used in aviation parts in developed countries,...Read more -

Metal Material Process

1. Castability (castability) Refers to the performance of metal materials that can obtain qualified castings by casting methods. Castability mainly includes fluidity, shrinkage and segregation. Fluidity refers to the ability of liquid metal to fill the mold, shrinkage refers to the degree of volu...Read more -

TIG welding

TIG welding technology is based on the principle of ordinary TIG #welding, using argon gas to protect the metal welding material, and through high current to make the welding material melt into a liquid state on the base material to be welded to form a molten pool, so that the welded metal and th...Read more -

Stainless Steel

Stainless Steel (Stainless Steel) is a high-alloy steel that is resistant to corrosion. It has a beautiful surface and does not need surface treatment such as color plating or paint. Therefore, many machinery factories often do not do any paint treatment in order to show that they are stainless s...Read more -

Surface Treatment-Plating

Principle: Electroplating is an electrochemical and redox process. Take nickel plating as an example: the metal part is immersed in the solution of metal salt (NiS04) as the cathode, and the metal nickel plate is used as the anode. After the direct current power supply is turned on, the metal nic...Read more -

Phosphating

Advantages of phosphating The high-temperature manganese phosphating film has the characteristics of dense film layer, good wear resistance, and excellent anti-corrosion and anti-rust performance. Because the phosphating film has a large specific surface area and good adsorption capacity, it is w...Read more -

Three ways of welding

Welding achieves the purpose of joining through the following three ways: 1. Fusion welding – heating the workpieces to be joined to make them partially melt to form a molten pool, and then join after the molten pool is cooled and solidified. If necessary, fillers can be added to assist. It...Read more -

Surface Treatment-Phosphating process

I. Overview: Steel parts (such as fasteners) go through a series of chemical and electrochemical reactions in a solution containing phosphate. The process of forming a phosphate protective film that is difficult to dissolve in water on the surface is called phosphating of steel. . The color of th...Read more -

Several Heat Treatment Methods of Carburizing

The heat treatment process of carburized steel includes preparatory heat treatment and carburizing and quenching process, in which heat treatment includes ordinary normalizing, isothermal normalizing, normalizing + tempering, and isothermal annealing. Carburizing and quenching mainly includes pre...Read more -

Composition characteristics of carburizing steel

The carbon content of carburized steel is generally very low (between 0.15% and 0.25%), which belongs to low carbon steel. Such carbon content ensures that the core of carburized parts has good toughness and plasticity. In order to improve the strength of the core of the steel, a certain amount o...Read more -

Carburizing and quenching-Heat treatment

The main heat treatment process of carburizing steel is generally quenching and low temperature tempering after carburizing. The core of the treated part is a low-carbon martensite structure with sufficient strength and toughness, and the surface layer is hard and wear-resistant tempered martensi...Read more