Hot-selling Machining Parts Supplier - Copper casting – Neuland Metals

Hot-selling Machining Parts Supplier - Copper casting – Neuland Metals Detail:

Bronze casting are a kind of copper alloy material which are widely used in the machinery manufacturing industry, ship building, automotive and construction industries. The most popular sorts of bronze castings can be classified as Cu-Sn, Cu-Al, Cu-Pb, Cu-Mn castings. Below are the common grade of

|

Grade |

Element % | Application |

|

ZQSnD10-1 |

Cu-10Sn-1p | Wear resisting parts under heavy duty and high sliding speed |

|

ZQSnD10-2 |

Cu-10Sn-2Zn | Complicated design casting, valves, pump, gear, and turbo |

|

ZQSnD10-5 |

Cu-10Sn-5Pb | structural material, anti corrosion and anti acid parts |

|

ZQSnD6-6-3 |

Cu-6Sn-6Zn-3Pb | Parts working under friction conditions, such as bushing. |

|

ZQSnD5-5-5 |

Cu-5Sn-5Zn-5Pb | Wear and corrosion resistant parts that operate under high loads and at moderate sliding speeds |

|

ZQPbD10-10 ZQPbD15-8 ZQPbD17-4-4 |

Cu-10Sn-10Pb | Automotive part and other heavy duty parts |

| Cu-15Pb-8Sn | Anti acid parts and parts working under high pressure. | |

| Cu-17Pb-4Sn-4Zn | High sliding speed bearing and general wear resistant parts | |

|

ZQMnD12-8-3 |

Cu-13Mn-8Al-3Fe | Heavy duty machinery bushing and high strength wear resistant, pressure loading part |

|

QMnD12-8-3-2 |

Cu-13Mn-8Al-3Fe-2Ni | High strength anti corrosion, wear resistant and pressure loading parts. |

|

ZQAlD9-4-4-2 |

Cu-9.4Al-4.5Fe-4.5Ni-1.5Mn | Anti corrision, high strength casting. Wear resistant and parts working in high temperature. |

The copper alloy with zinc as the main alloying element is usually called brass. Copper-zinc binary alloy called ordinary brass. With more alloy element added to the material based on copper-zinc alloy, it will be called special brass. Brass casting is widely applied in machinery industry, ship building, aerospace, automotive, construction, etc. The main characteristics of brass casting are wear resistance and anti rust features. Normal production methods for brass castings are die casting, centrifugal casting, lost wax casting and sand casting.

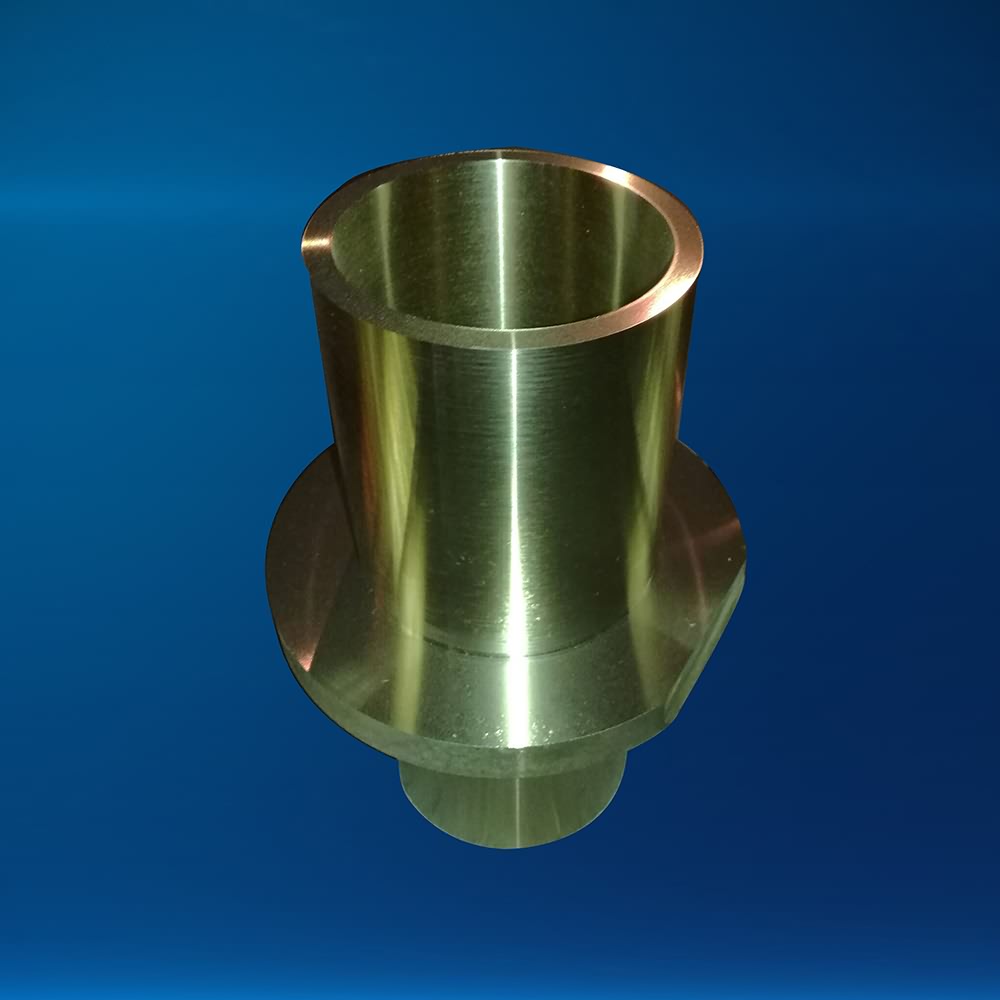

Product detail pictures:

Related Product Guide:

"Sincerity, Innovation, Rigorousness, and Efficiency" may be the persistent conception of our organization to the long-term to build together with shoppers for mutual reciprocity and mutual advantage for Hot-selling Machining Parts Supplier - Copper casting – Neuland Metals , The product will supply to all over the world, such as: Germany, Colombia, Turkey, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

This manufacturers not only respected our choice and requirements, but also gave us a lot of good suggestions, ultimately, we successfully completed the procurement tasks.