Custom Stainless Steel Casting - China Factory, Suppliers, Manufacturers

As a way to ideal meet up with client's desires, all of our operations are strictly performed in line with our motto "High Top quality, Competitive Cost, Fast Service" for Custom Stainless Steel Casting, Precision Cast Parts, Stamping Supplier, Aluminum Foundry,Brass Cast Manufacturer. If you are interested in any of our products or would like to discuss a customized order, please feel free to contact us. The product will supply to all over the world, such as Europe, America, Australia,Swedish, Sao Paulo,belarus, Sevilla.In the new century, we promote our enterprise spirit "United, diligent, high efficiency, innovation", and stick to our policy"basing on quality, be enterprising, striking for first class brand". We would take this golden opportunity to create bright future.

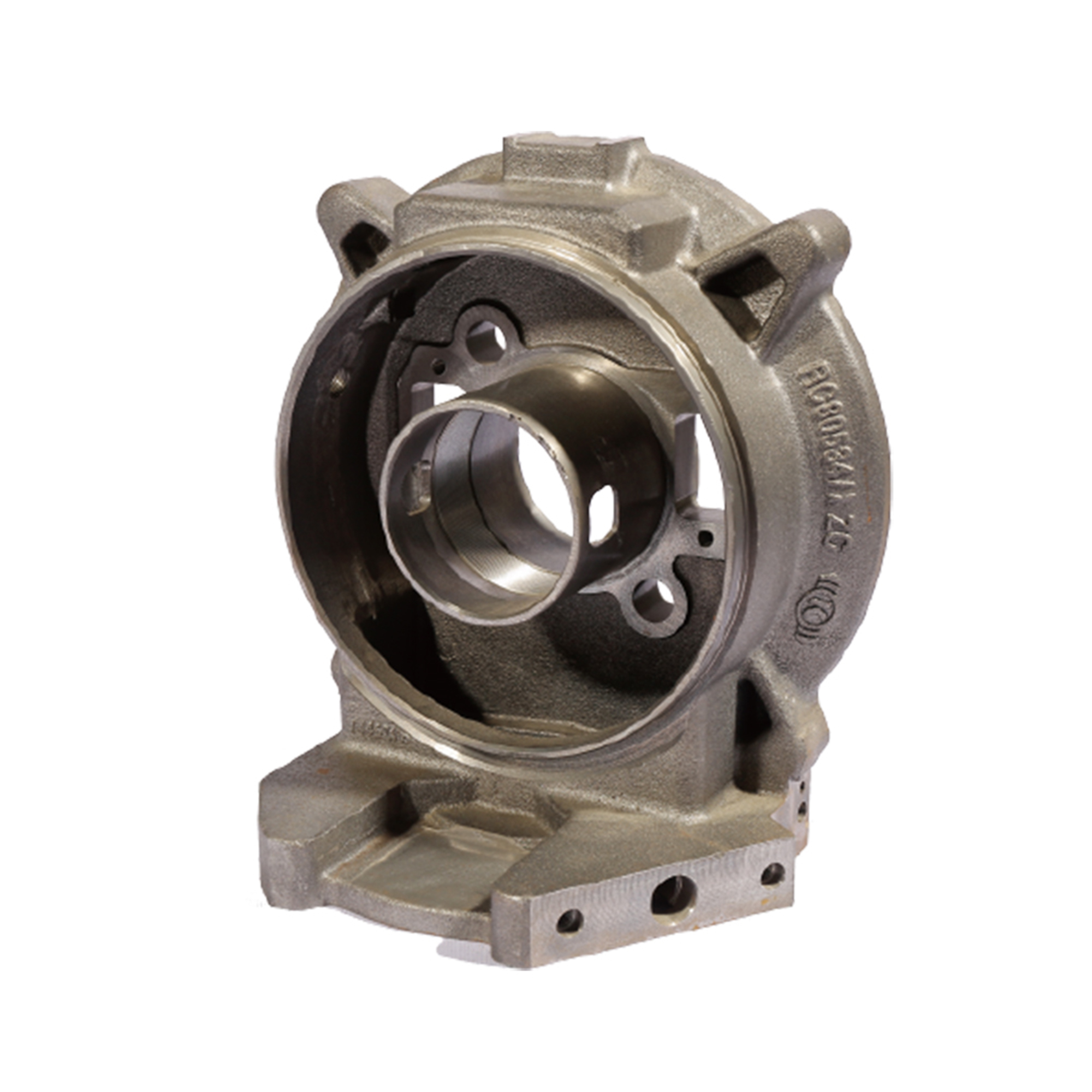

Related Products