Stainless Steel Precision Turned Parts - Manufacturers, Suppliers, Factory from China

We constantly think and practice corresponding to the change of circumstance, and grow up. We aim at the achievement of a richer mind and body along with the living for Stainless Steel Precision Turned Parts, Steel Cold Former, Precision Turned Products Manufacturer, Cast Iron Parts,Custom Aluminum Casting. We have been sincerely looking forward to developing very good cooperative relationships with buyers from at home and abroad for creating a vibrant foreseeable future together. The product will supply to all over the world, such as Europe, America, Australia,Mexico, Detroit,Comoros, Bahrain.We attained ISO9001 which provides solid foundation for our further development. Persisting in "High quality, Prompt Delivery, Competitive Price", we have established long-term cooperation with clients from both overseas and domestically and get new and old clients' high comments. It is our great honor to meet your demands. We are sincerely expecting your attention.

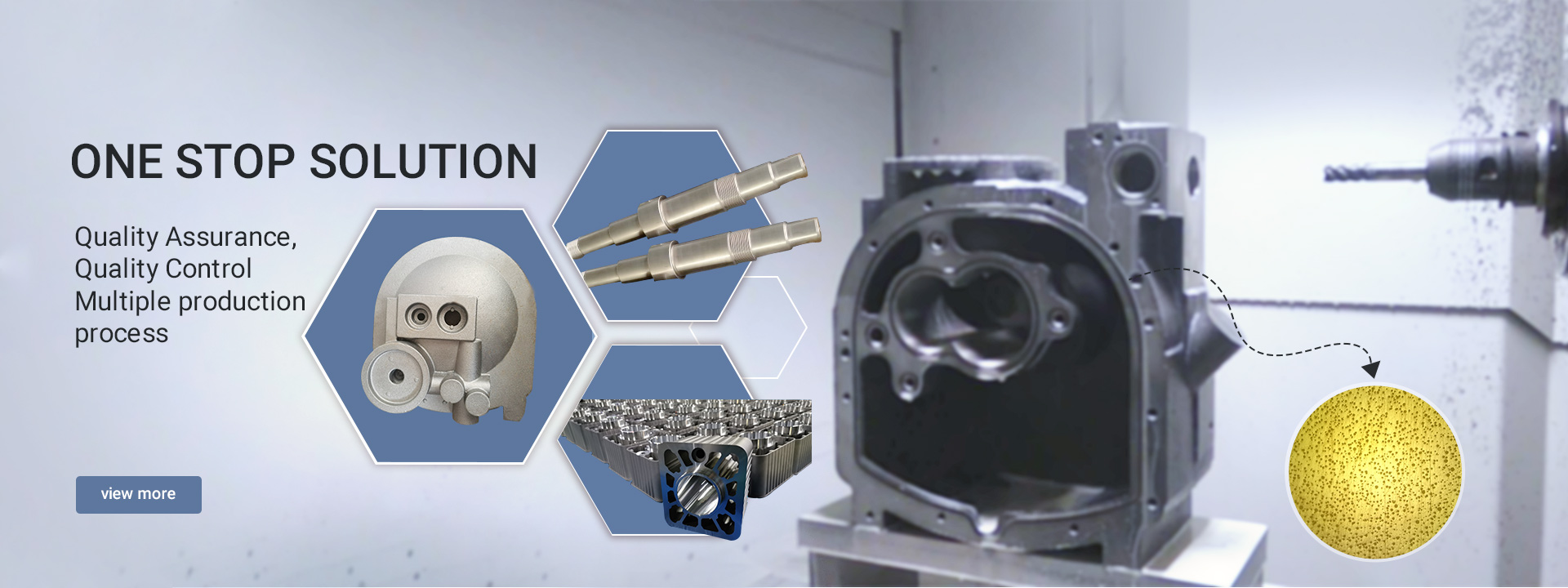

Related Products