Popular Design for Brass Cast Manufacturer - Steel casting – Neuland Metals

Popular Design for Brass Cast Manufacturer - Steel casting – Neuland Metals Detail:

Steel casting is one of the casting alloys and consists of mainly iron and Carbon. The steel casting is preferred to be adopted when the iron casting can not meet the requirement of the function, especially in terms of strength. Steel castings can be categorized into general structure steel casting, welding structural steel casting, stainless and high temperature steel casting according to usage. And chemically, steel castings can be called carbon steel and alloy steel. Furthermore, if based on its characteristics, the steel castings can be listed as tool steel, special steel, engineering & structure steel and alloy steel.

The advantage of steel castings are its flexibility and variability in designing and production, its much higher strength in structure, wider range of part weight.

Cast steels can be produced with a wide range of properties. The physical properties of cast steel change significantly depending on chemical composition and heat treatment. They are selected to match performance requirements of the intended application.

- Hardness

The ability of a material to withstand abrasion. Carbon content determines the maximum hardness obtainable in steel, or hardenability. - Strength

The amount of force necessary to deform a material. Higher carbon content and hardness result in steel with higher strength. - Ductility

The ability of a metal to deform under tensile stress. Lower carbon content and less hardness result in steel with higher ductility. - Toughness

The ability to withstand stress. Increased ductility is usually associated with better toughness. Toughness can be adjusted with the addition of alloying metals and heat treatment. - Wear resistance

The resistance of a material to friction and use. Cast steel exhibits similar wear resistance to that of wrought steels of similar composition. The addition of alloying elements such as molybdenum and chromium can increase wear resistance. - Corrosion resistance

The resistance of a material against oxidization and rust. Cast steel exhibits similar corrosion resistance to that of wrought steel. High-alloy steels with elevated levels of chromium and nickel are highly oxidation resistant. - Machinability

The ease at which a steel casting can change shape by removing material through machining (cutting, grinding, or drilling). Machinability is influenced by hardness, strength, thermal conductivity, and thermal expansion. - Weldability

The ability of a steel casting to be welded without defects. Weldability is primarily dependent on the steel casting’s chemical composition and heat treatment. - High-temperature properties

Steels operating at temperatures above ambient are subject to degraded mechanical properties and early failure due to oxidation, hydrogen damage, sulfite scaling, and carbide instability. - Low-temperature properties

The toughness of cast steel is severely reduced at low temperatures. Alloying and specialized heat treatments can improve a casting’s ability to withstand loads and stresses.

Steel casting is applied is nearly all the industries. Especially is the industries like power station, ship building, train, automotive, engineering vehicles, construction vehicles, mining industry, aerospace, energy, oil, chemical etc, steel castings are widely used.

For Steel casting, the process can be shell molding and Solidum silicate sand casting, both are a kind of sand casting process. And Investment casting process can also be applied. You can make the option based on the need of surface, cost and tolerance.

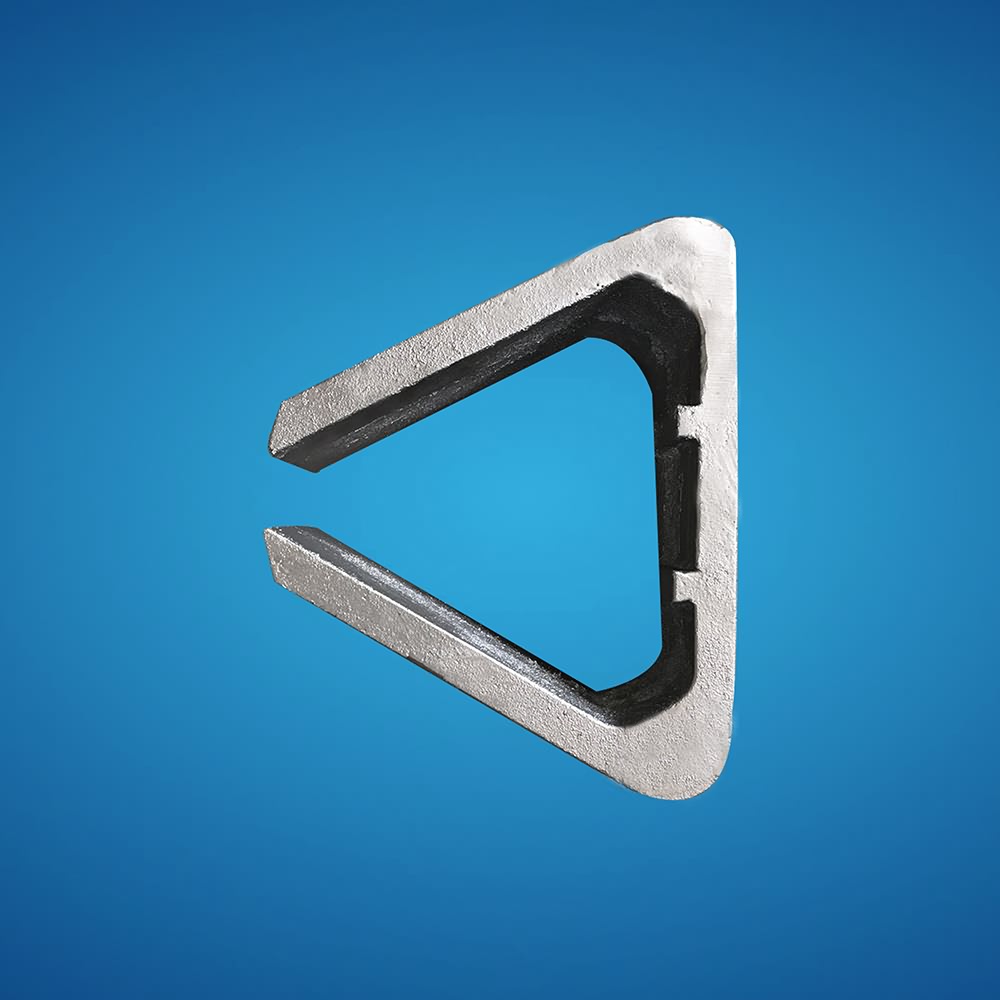

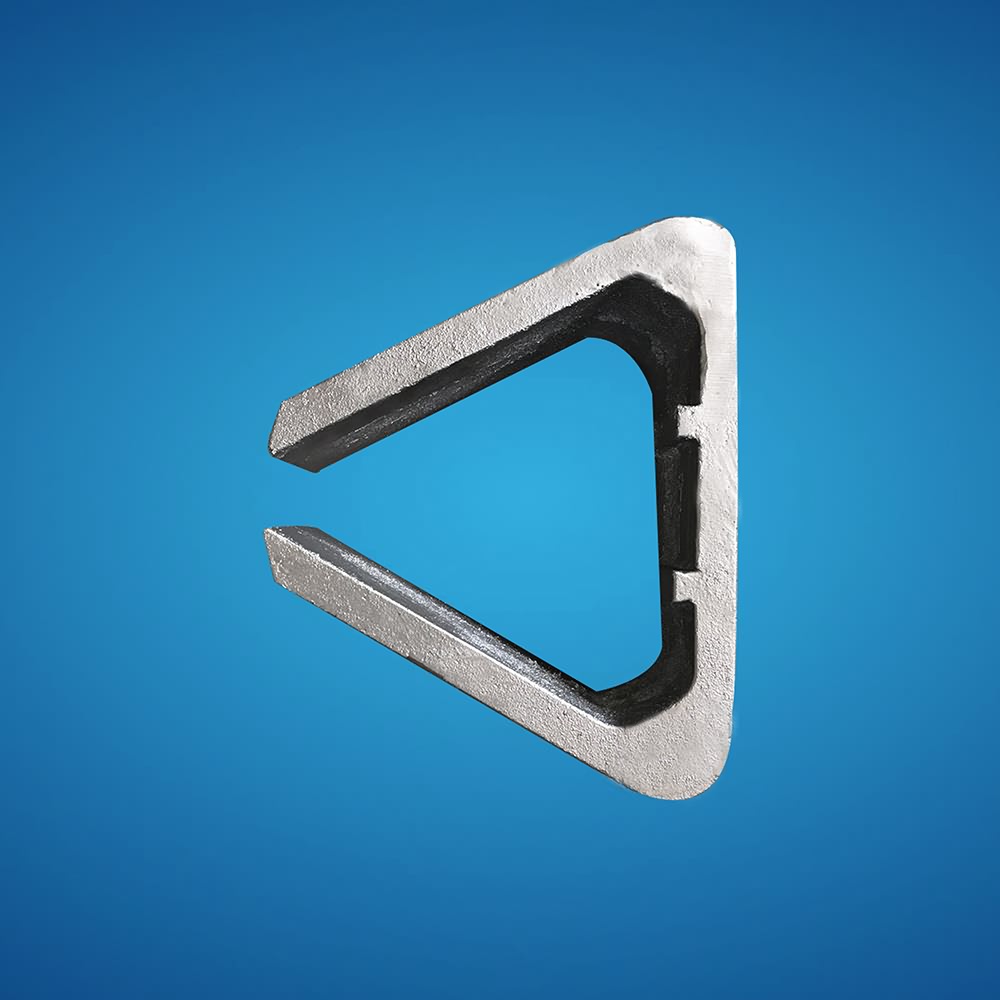

Product detail pictures:

Related Product Guide:

With responsible good quality method, good status and excellent client services, the series of solutions produced by our company are exported to lots of countries and regions for Popular Design for Brass Cast Manufacturer - Steel casting – Neuland Metals , The product will supply to all over the world, such as: Netherlands, Mongolia, New Zealand, our qualify products have good reputation from the world as its most competive price and our most advantage of after-sale service to the clients.we hope we can provide a safe, environmental products and super service to our clients from all of the world and establish strategic partnership with them by our professional standards and unremitting efforts.

The company can think what our think, the urgency of urgency to act in the interests of our position, can be said this is a responsible company, we had a happy cooperation!