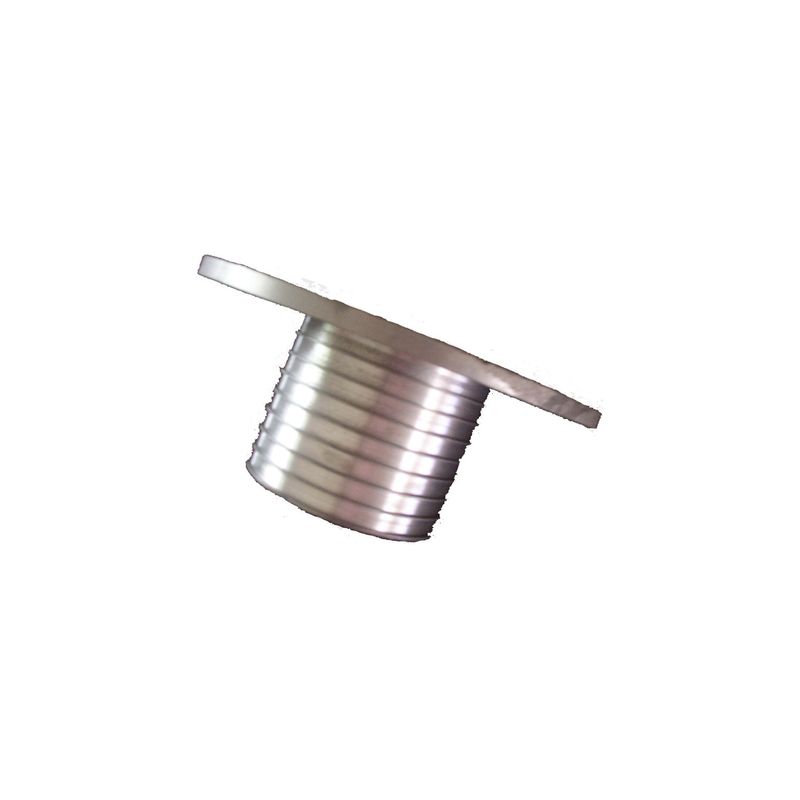

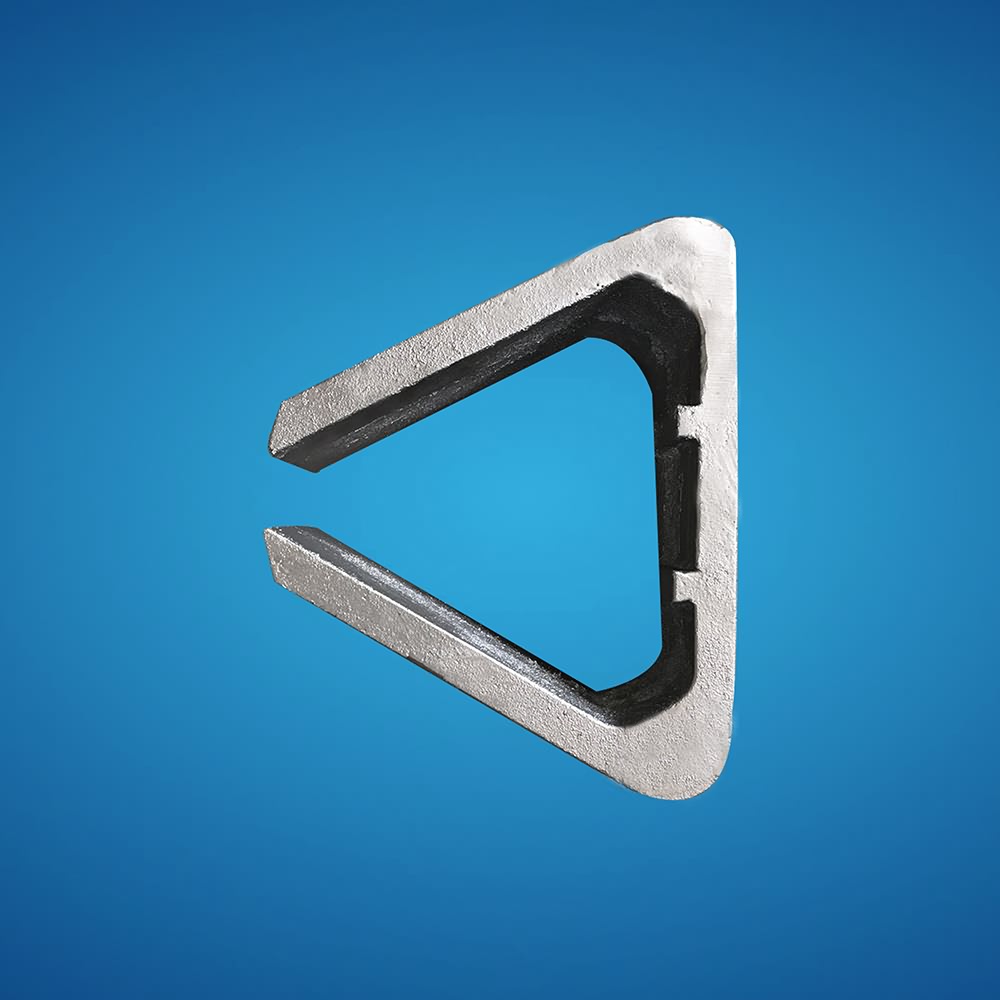

OEM Supply Precision Machining Parts Manufacturer - Iron casting – Neuland Metals

OEM Supply Precision Machining Parts Manufacturer - Iron casting – Neuland Metals Detail:

Iron casting normally produced through sand casting process. Sand casting as a technology has been selected as a preferred method to produce shaped parts that weigh from less than a pound to very large parts. The process is versatile and cost effective, even for low volume runs because of tooling cost. Nearly any part configuration that can be made using another casting process can be reduced to a pattern and created as a sand casting. Cast iron is a ferrous alloy of iron, carbon and silicon. With carbon content of 2.1 to 4.5 % and silicon at about 2.2% and small amount of Sulphur, Manganese and Phosphorous.

Iron casting is one of the oldest casting methods in the world. The cast iron is molten and poured into molds or casts to make a part of products of desired size and shape. The cast iron can be used in a wide range of industries. In the manufacturing process of Cast Iron, the alloying elements determine cast iron type. Compared with steel casting, iron casting has a wider range of advantages of its properties. The cast iron main types are Grey, Ductile, Compacted graphite, White, Malleable, Abrasion resistant and Austenitic.

Typical Applications for Iron Castings:

– Engineering Castings

– Heavy Engineering Plant & Equipment

– Original Equipment Manufacturers

– Petrochemical & Oil Production Sector

– Aerospace Applications

– Shipping Construction

– Transportation Infrastructure & Railway Stock

– Mining, Quarrying & Minerals

– Energy Sector & Power Production

– Hydro Applications

– Pump & Valve Manufacturers

– Rolling Mills & Steel Production

– Special Engineering Cast Iron Castings

– Architectural Castings

– Decorative Castings

The most popular molding methods for casting iron part are green sand molding, shell molding, resin sand molding and lost foam method.

With the great development in the past years, all our production is fairly automatic with molding lines such as vertical or horizontal molding lines, automatic pouring machine are introduced.

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for OEM Supply Precision Machining Parts Manufacturer - Iron casting – Neuland Metals , The product will supply to all over the world, such as: French, Bulgaria, Vietnam, We follow up the career and aspiration of our elder generation, and we are eager to open up a new prospect in this field, We insist on "Integrity, Profession, Win-win Cooperation", because we have a strong backup, that are excellent partners with advanced manufacturing lines, abundant technical strength, standard inspection system and good production capacity.

Production management mechanism is completed, quality is guaranteed, high credibility and service let the cooperation is easy, perfect!