OEM China Copper Investment Casting - Aluminum casting – Neuland Metals

OEM China Copper Investment Casting - Aluminum casting – Neuland Metals Detail:

For aluminum parts, they can be shaped through sand casting, permanent mold casting and die casting process.

Die casting is a manufacturing process for producing accurately dimensioned, sharply defined, smooth or textured-surface metal parts. It is accomplished by forcing molten metal under high pressure into reusable metal dies. The process is often described as the shortest distance between raw material and finished product. The term “die casting” is also used to describe the finished part.

The term “permanent mold casting” also called “gravity die casting” It refers to castings made in metal molds under a gravity head.

Permanent mold casting uses steel or other metal molds and cores. Strong castings are formed by pouring aluminum into the mold. Permanent molds are used to create highly repeatable parts with consistency. Their rapid cooling rates generate a more consistent microstructure, which can improve the mechanical properties significantly.

Permanent mold casting is used for creating alloy wheels. Aluminum wheels are also lighter than steel wheels, requiring less energy to rotate. They provide greater fuel efficiency, as well as better handling, acceleration, and braking. However, for heavy-duty industrial track applications, steel wheels are more commonly used. Their durability makes them almost impossible to bend or crack. When used on a track, steel wheels are more forgiving of track irregularities, increasing safety.

Sand castings are created by packing a fine sand mixture around a pattern of the desired product. The pattern is slightly larger than the final product to allow for shrinkage of the aluminum while cooling. Sand casting is economical because the sand can be reused multiple times. It is also effective for creating large moldings or those with detailed designs. Upfront tooling costs are low, but per-part prices are higher, making sand casting suitable for specialized castings over mass production.

Aluminum casting with its small density, the corrosion resistance and a number of excellent features, are more widely used in aerospace, vehicle, machinery and other industries. Especially in the automotive industry, in order to reduce fuel consumption to improve energy utilization, more and more parts of automobile are being adapted into aluminum materials.

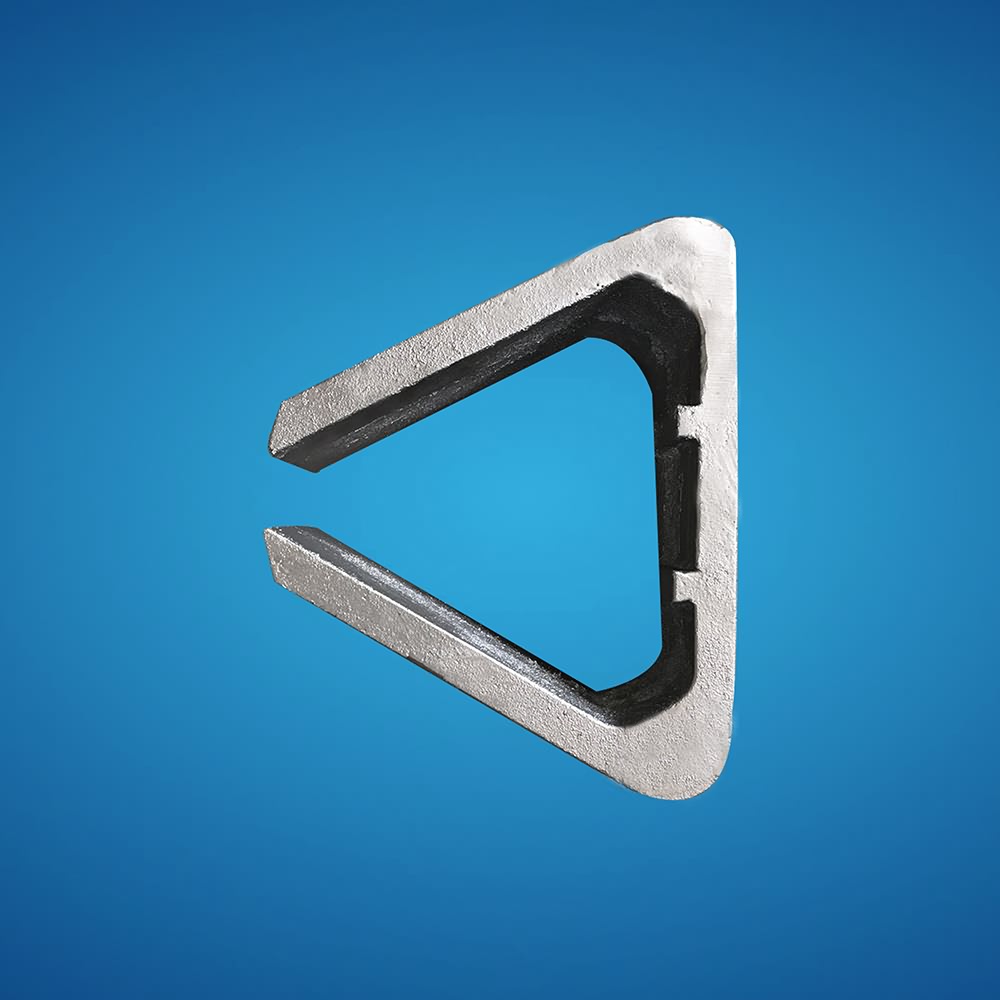

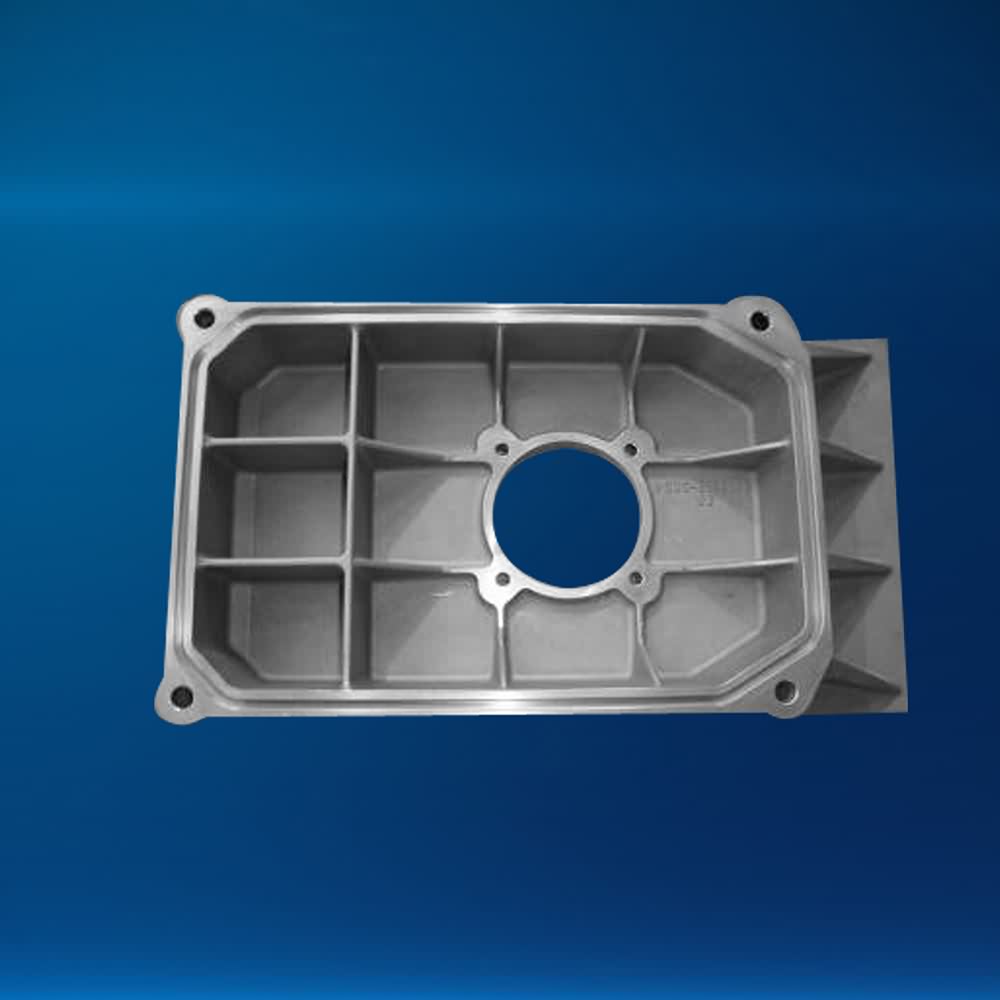

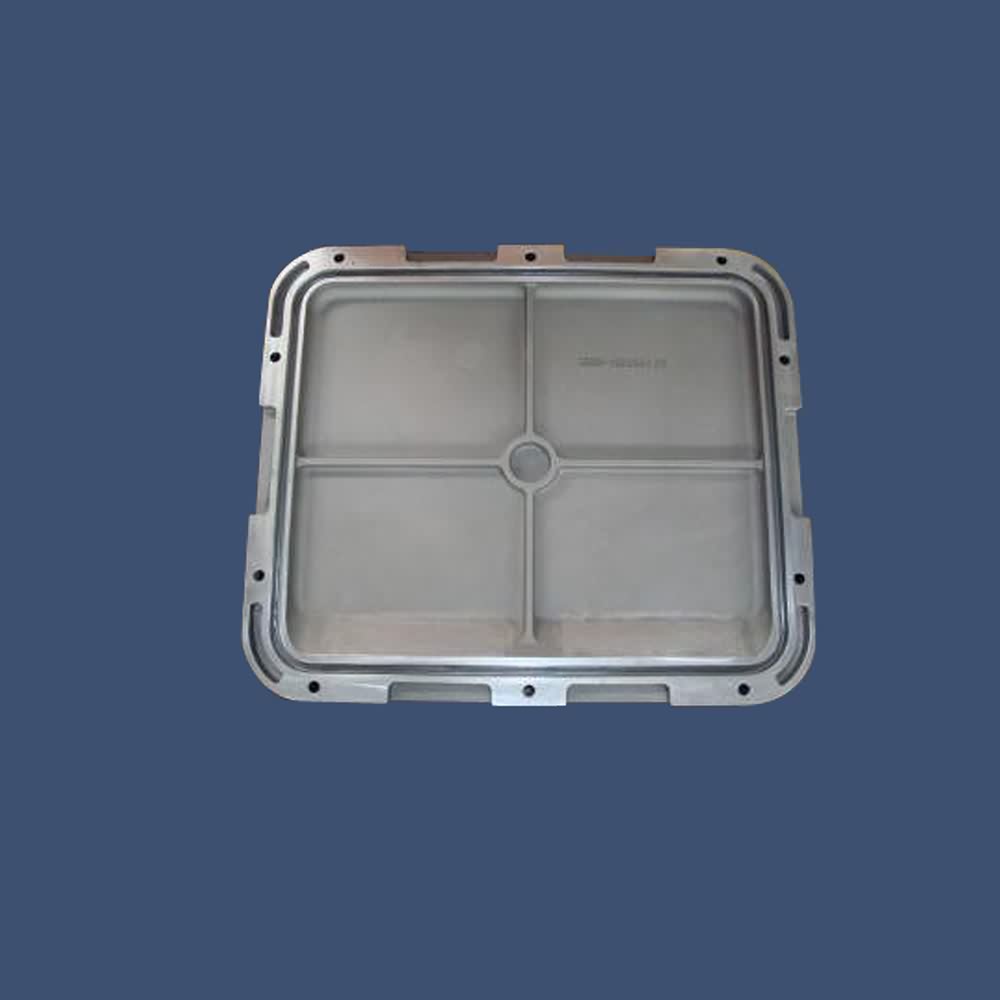

Product detail pictures:

Related Product Guide:

Our pursuit and firm aim should be to "Always fulfill our buyer requirements". We carry on to produce and structure top-quality excellent solutions for equally our aged and new consumers and accomplish a win-win prospect for our consumers as well as us for OEM China Copper Investment Casting - Aluminum casting – Neuland Metals , The product will supply to all over the world, such as: Cairo, Lyon, Nepal, We now have been making our goods for more than 20 years . Mainly do wholesale , so we've the most competitive price , but highest quality. For the past years , we got very good feedbacks , not only because we offer good solutions , but also because of our good after-sale service . We are here waiting for yourself for your inquiry.

We always believe that the details decides the company's product quality, in this respect, the company conform our requirements and the goods are meet our expectations.