News

-

What is cold drawn steel?

Cold-drawn steel uses hot-rolled steel as raw material, and the product quality is better than that of hot-rolled steel. For example, the cold-drawn profile causes metal work hardening due to cold deformation, which increases the tensile strength and yield strength of the cold-drawn material, and...Read more -

Ultrasonic Testing Technology-Neuland

Ultrasonic flaw detection is an advanced method of inspecting parts for defects. It mainly uses the characteristics of ultrasonic energy penetrating into the depths of metal materials, and judges whether there is a defect through the reflection that occurs at the edge of the interface when...Read more -

Gray iron properties and applications

(1) Mechanical properties The structure of gray cast iron is equivalent to taking steel as the matrix and adding flake graphite. The matrix contains more elements such as silicon and manganese than steel. These elements can dissolve into ferrite to strengthen the matrix, so the strength and hardn...Read more -

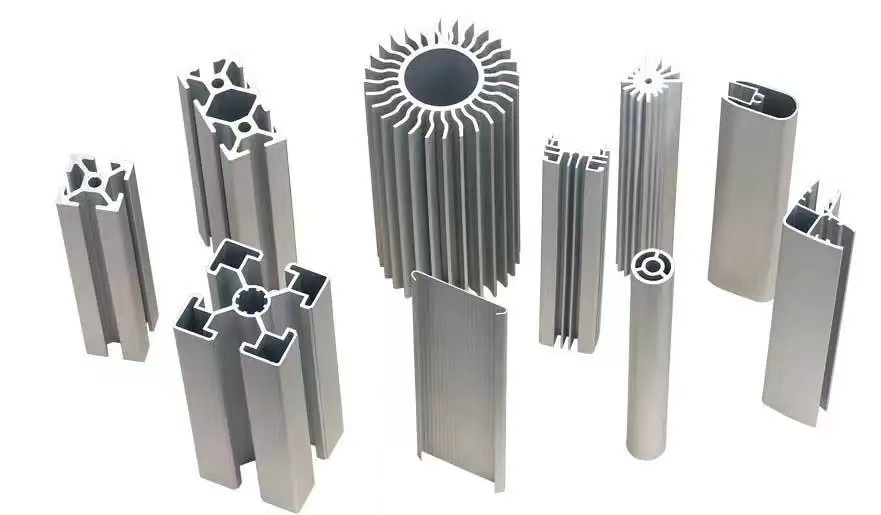

What is Profile Extrusion?

Principle of extrusion of aluminum profiles :Aluminum extrusion is a plastic processing method that applies external force to a metal blank placed in a container (extrusion cylinder) to make it flow out from a specific die hole to obtain the desired cross-sectional shape and size. Second, the co...Read more -

Heat Treatment

Heat treatment refers to a metal thermal processing process in which the material is in a solid state by means of heating, heat preservation and cooling to obtain the expected structure and properties. In the process from the Stone Age to the Bronze Age and Iron Age, the role of heat treatment is...Read more -

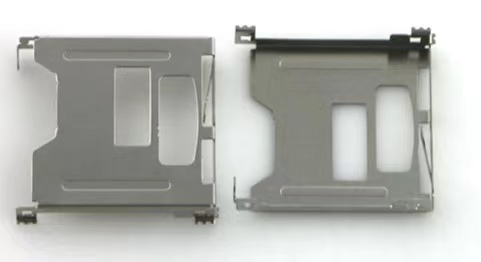

What is Stamping?

Stamping is a forming and processing method that applies external forces to plates, strips, pipes and profiles by means of presses and dies to produce plastic deformation or separation, so as to obtain the workpiece (stamping part) with the required shape and size. Stamping and forging belong to ...Read more -

What is sand casting

Sand casting refers to the casting method of producing castings in sand mold. Steel, iron and most non-ferrous alloy castings can be obtained by sand casting. Because the molding materials used in sand casting are cheap and easy to obtain, and the mold manufacturing is simple, it can adapt to the...Read more -

The difference between free forging and die forging

Model forging is a method in which metal is plastically deformed under the action of external force and fills the die cavity to obtain forgings. Commonly used die forging equipment includes die forging hammer, hot die forging press, flat forging machine and friction press. Compared with free forg...Read more -

What is Forging

Forging is a processing method that uses forging machinery to exert pressure on metal blanks to produce plastic deformation to obtain forgings with certain mechanical properties, shapes and sizes. It is one of the two major components of forging (forging and stamping). Forging can eliminate the d...Read more -

The Application of Forgings

Forging products are usually formed by a certain forging process, and its application range is very wide. In industry, manufacturing, etc. show their talents. Hefei forging accounts for a large proportion of forging in the country. Let’s take a look at the fields of application. Aircraft fo...Read more -

Meaning and process of stamping

#Stamping process is a metal processing method, it is based on the plastic deformation of metal, the use of mold and# stamping equipment to exert pressure on the sheet, so that the sheet plastic deformation or separation, so as to obtain a certain shape, size and performance of the parts (stampin...Read more -

Wear-resistant steel

There are many kinds of wear-resistant steel, which can be roughly divided into high manganese steel, medium and low alloy wear-resistant steel, chrome-molybdenum-silicon-manganese steel, cavitation-resistant steel, wear-resistant steel and special wear-resistant steel. Some general alloy steels ...Read more