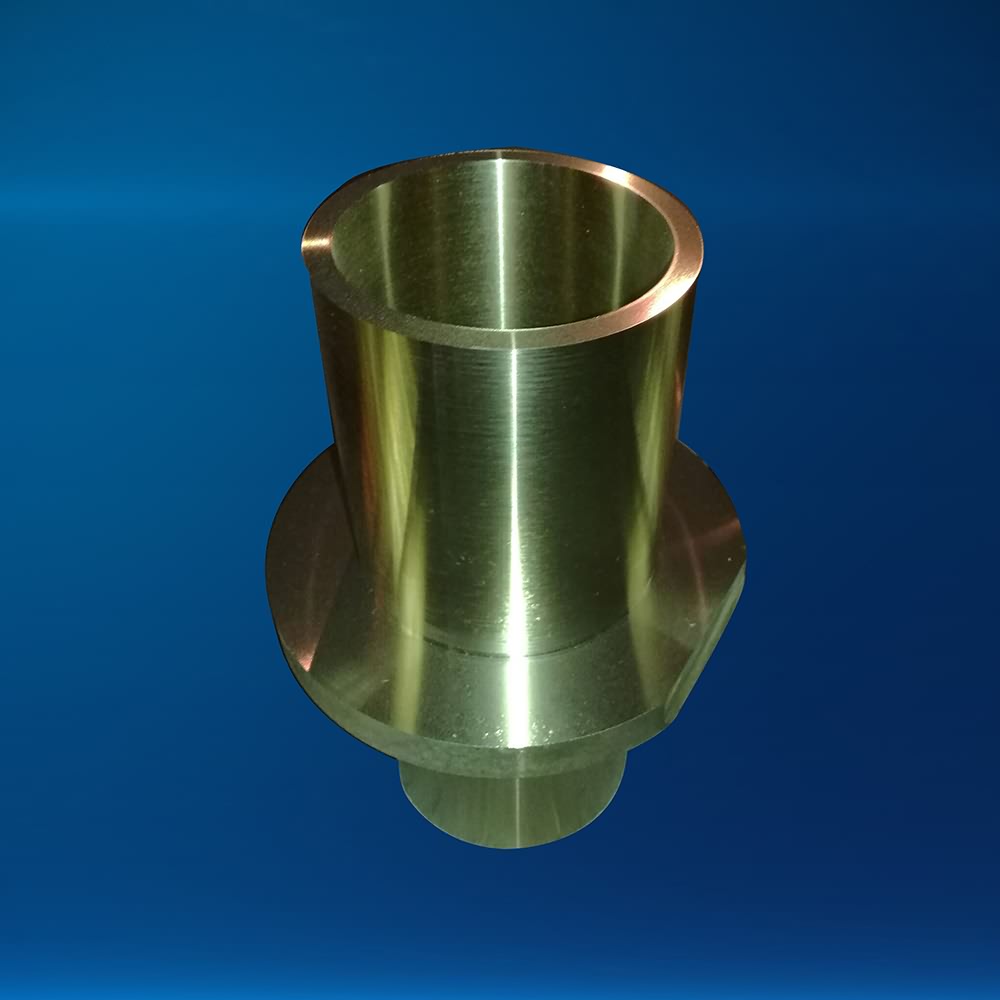

High Quality Cold Former - Copper casting – Neuland Metals

High Quality Cold Former - Copper casting – Neuland Metals Detail:

Bronze casting are a kind of copper alloy material which are widely used in the machinery manufacturing industry, ship building, automotive and construction industries. The most popular sorts of bronze castings can be classified as Cu-Sn, Cu-Al, Cu-Pb, Cu-Mn castings. Below are the common grade of

|

Grade |

Element % | Application |

|

ZQSnD10-1 |

Cu-10Sn-1p | Wear resisting parts under heavy duty and high sliding speed |

|

ZQSnD10-2 |

Cu-10Sn-2Zn | Complicated design casting, valves, pump, gear, and turbo |

|

ZQSnD10-5 |

Cu-10Sn-5Pb | structural material, anti corrosion and anti acid parts |

|

ZQSnD6-6-3 |

Cu-6Sn-6Zn-3Pb | Parts working under friction conditions, such as bushing. |

|

ZQSnD5-5-5 |

Cu-5Sn-5Zn-5Pb | Wear and corrosion resistant parts that operate under high loads and at moderate sliding speeds |

|

ZQPbD10-10 ZQPbD15-8 ZQPbD17-4-4 |

Cu-10Sn-10Pb | Automotive part and other heavy duty parts |

| Cu-15Pb-8Sn | Anti acid parts and parts working under high pressure. | |

| Cu-17Pb-4Sn-4Zn | High sliding speed bearing and general wear resistant parts | |

|

ZQMnD12-8-3 |

Cu-13Mn-8Al-3Fe | Heavy duty machinery bushing and high strength wear resistant, pressure loading part |

|

QMnD12-8-3-2 |

Cu-13Mn-8Al-3Fe-2Ni | High strength anti corrosion, wear resistant and pressure loading parts. |

|

ZQAlD9-4-4-2 |

Cu-9.4Al-4.5Fe-4.5Ni-1.5Mn | Anti corrision, high strength casting. Wear resistant and parts working in high temperature. |

The copper alloy with zinc as the main alloying element is usually called brass. Copper-zinc binary alloy called ordinary brass. With more alloy element added to the material based on copper-zinc alloy, it will be called special brass. Brass casting is widely applied in machinery industry, ship building, aerospace, automotive, construction, etc. The main characteristics of brass casting are wear resistance and anti rust features. Normal production methods for brass castings are die casting, centrifugal casting, lost wax casting and sand casting.

Product detail pictures:

Related Product Guide:

Generally customer-oriented, and it's our ultimate goal for being not only the most trusted, trustable and honest provider, but also the partner for our customers for High Quality Cold Former - Copper casting – Neuland Metals , The product will supply to all over the world, such as: Israel, Cologne, Munich, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The company leader recept us warmly, through a meticulous and thorough discussion, we signed a purchase order. Hope to cooperate smoothly