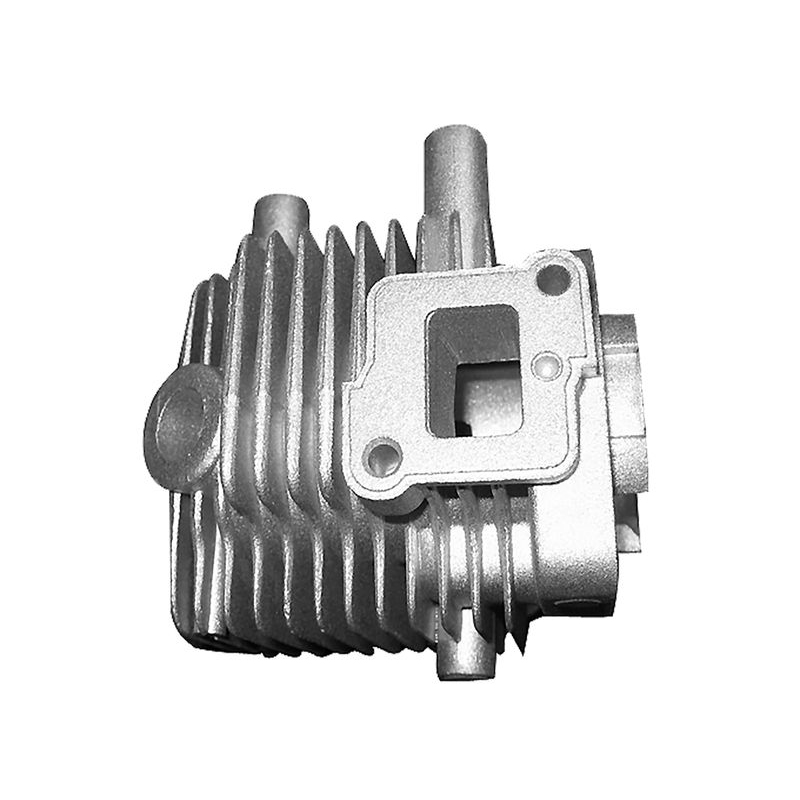

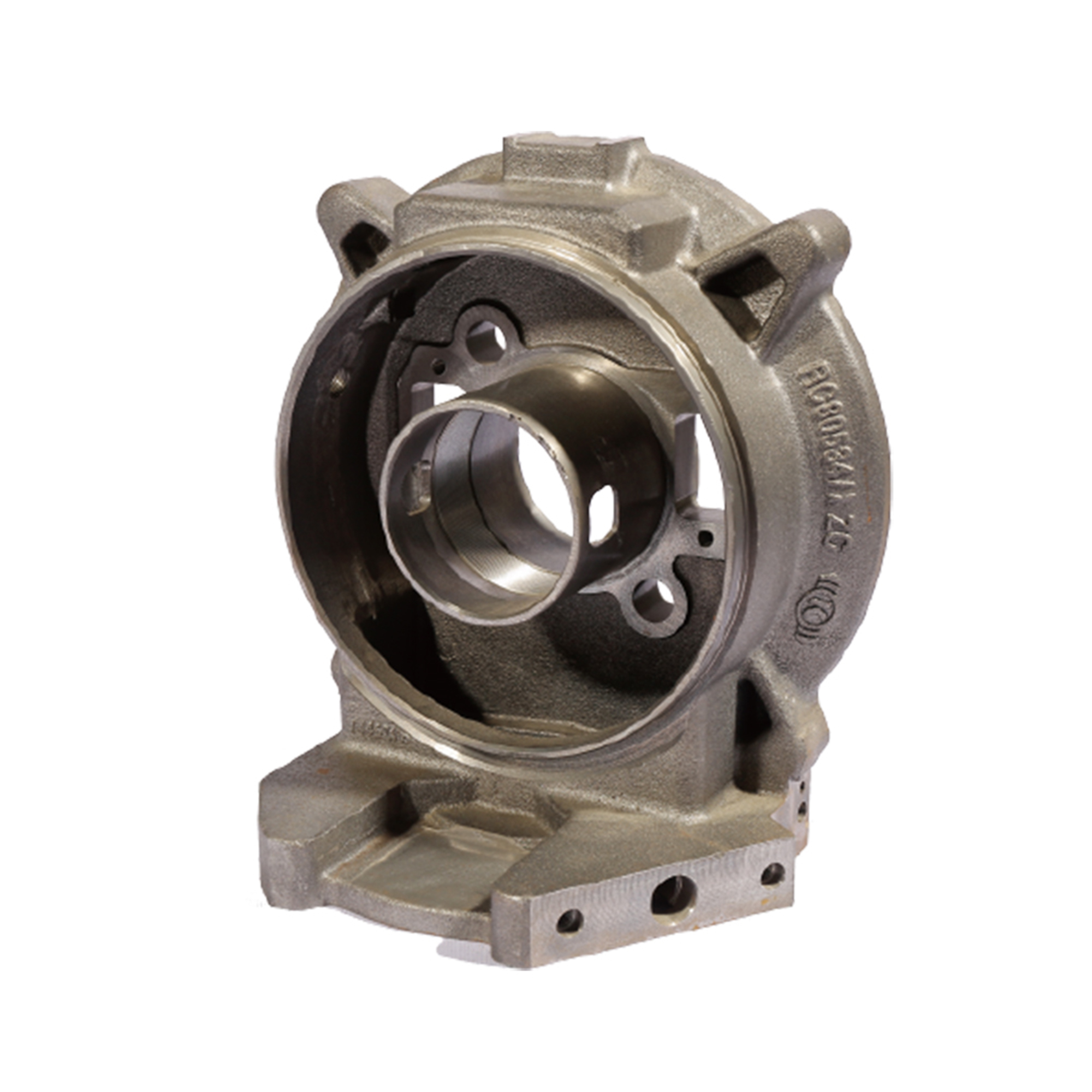

Grey Iron Casting Parts - Manufacturers, Suppliers, Factory from China

Gaining purchaser gratification is our company's aim eternally. We're going to make great initiatives to create new and top-quality products, satisfy your exclusive prerequisites and supply you with pre-sale, on-sale and after-sale solutions for Grey Iron Casting Parts, Brass Casting Supplier, Forged Aluminum Supplier, Aluminum Precision Machining Parts,Lost Wax Casting Parts. If you are looking for Good Quality at a good price and timely delivery. Do contact us. The product will supply to all over the world, such as Europe, America, Australia,Pretoria, France,Johannesburg, Angola.We welcome you to visit our company, factory and our showroom displayed various products that will meet your expectation, meanwhile, it is convenient to visit our website, our sales staff will try their efforts to provide you the best service. If you need more information, please do not hesitate to contact us by E-mail or telephone.

Related Products