Bottom price Precision Machining Parts Supplier - Forging parts – Neuland Metals

Bottom price Precision Machining Parts Supplier - Forging parts – Neuland Metals Detail:

Material: carbon, alloy and stainless steels; very hard tool steels; aluminum; brass and copper; and high-temperature alloys

Processing: Die forging or free forging

Weight:1-1000KG

Processing capacity: Diameter 10mm-6000mm

Forging is manufacturing process where metal is pressed, pounded or squeezed under great pressure into high strength parts known as forgings. The process is normally (but not always) performed hot by preheating the metal to a desired temperature before it is worked. It is important to note that the forging process is entirely different from the casting (or foundry) process, as metal used to make forged parts is never melted and poured (as in the casting process).

The forging process can create parts that are stronger than those manufactured by any other metalworking process. This is why forgings are almost always used where reliability and human safety are critical. But forging parts can rarely be seen because normally the parts are assembled inside of machinery or equipment, like ships, oil drilling facilities, engines, automobiles, tractors, etc.

The most common metals that can be forged include: carbon, alloy and stainless steels; very hard tool steels; aluminum; titanium; brass and copper; and high-temperature alloys which contain cobalt, nickel or molybdenum. Each metal has distinct strength or weight characteristics that best apply to specific parts as determined by the customer.

Forging is categorized into hot forging, warm forging and cold forging in terms of temperature.

While according to its forming procedures, forging can also be classified as free forging, die forging, and special forging.

Forging parts are widely used in industries like air plane, diesel engine, ships, military, mining industry, nuclear power, oil&gas, chemical, etc.

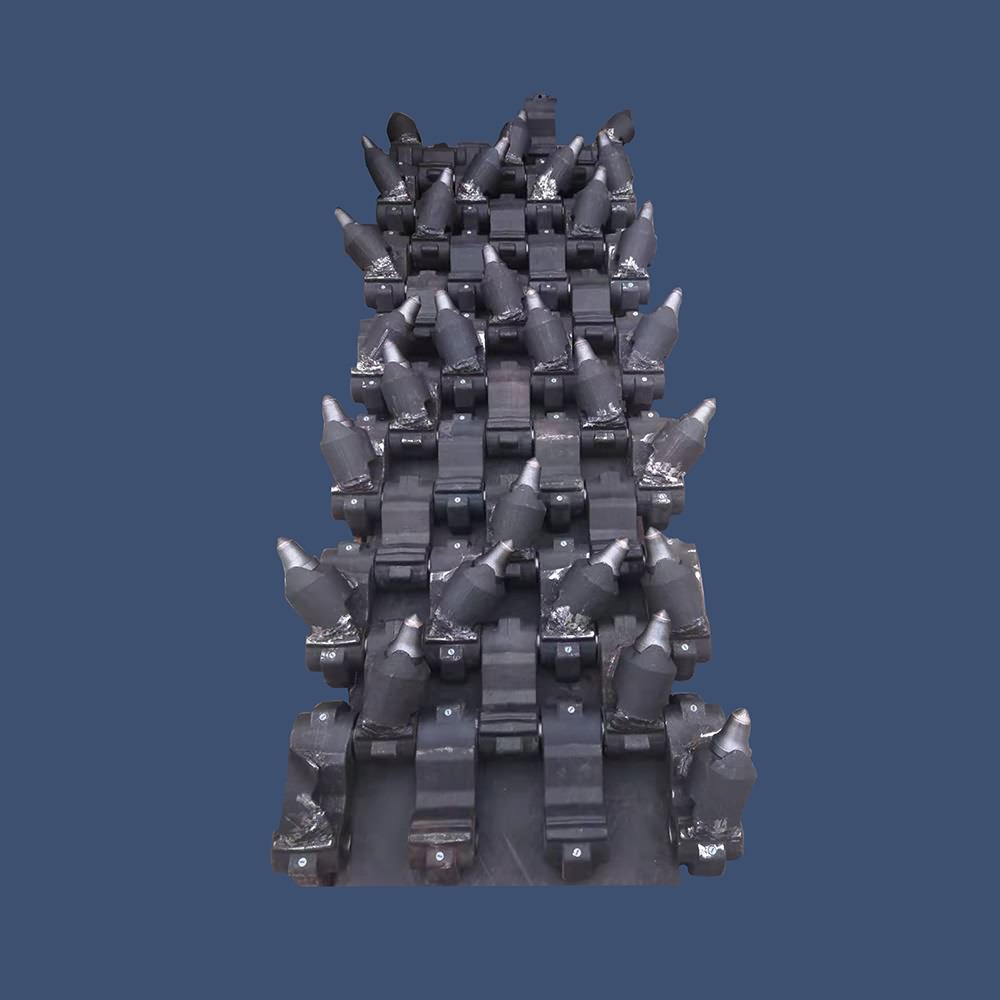

Product detail pictures:

Related Product Guide:

Bear "Customer 1st, Good quality first" in mind, we work closely with our prospects and supply them with efficient and professional services for Bottom price Precision Machining Parts Supplier - Forging parts – Neuland Metals , The product will supply to all over the world, such as: Turkmenistan, London, Ghana, Qualified R&D engineer will be there for your consultation service and we will try our best to meet your requirements. So please feel free to contact us for inquiries. You'll be able to send us emails or call us for small business. Also you are able to come to our business by yourself to get further knowing of us. And we will surely give you the best quotation and after-sale service. We're ready to build stable and friendly relations with our merchants. To achieve mutual success, we will make our best efforts to build a solid co-operation and transparent communication work with our companions. Above all, we are here to welcome your inquiries for any of our goods and service.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.