Best quality Custom Forged Parts - Copper casting – Neuland Metals

Best quality Custom Forged Parts - Copper casting – Neuland Metals Detail:

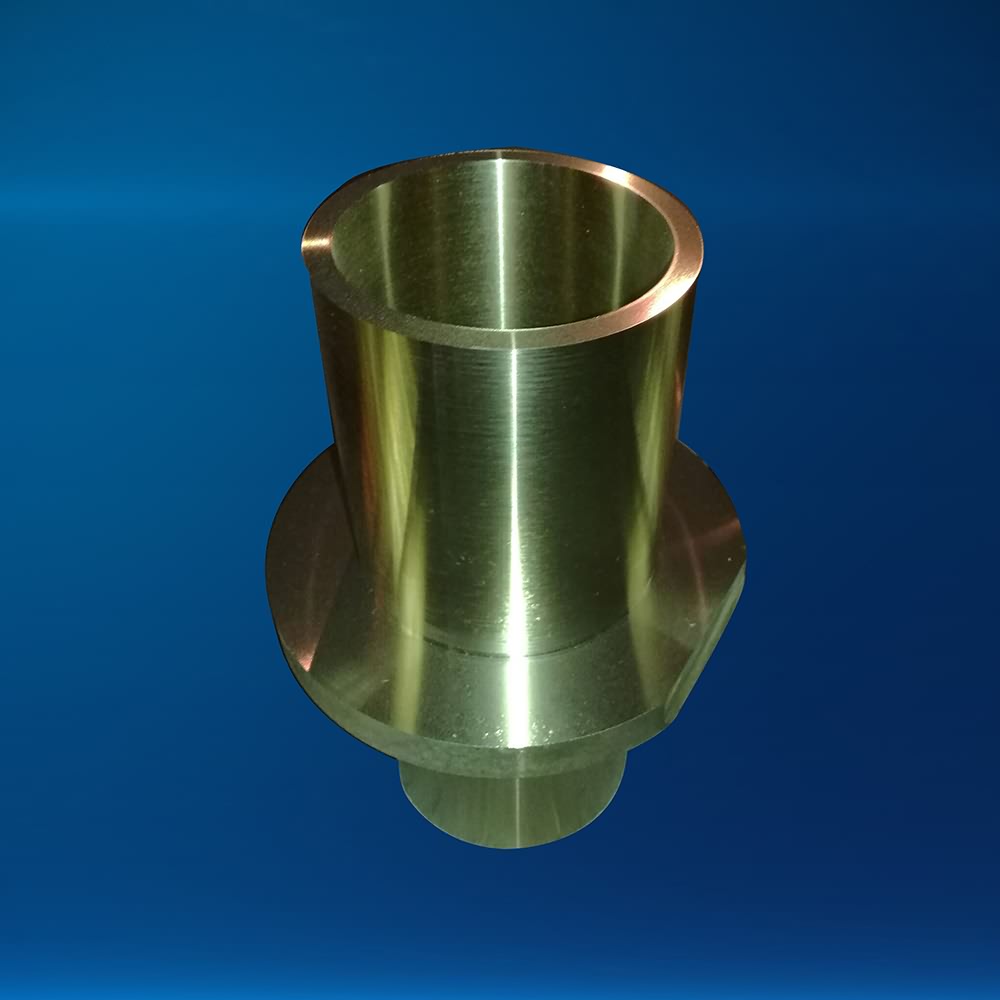

Bronze casting are a kind of copper alloy material which are widely used in the machinery manufacturing industry, ship building, automotive and construction industries. The most popular sorts of bronze castings can be classified as Cu-Sn, Cu-Al, Cu-Pb, Cu-Mn castings. Below are the common grade of

|

Grade |

Element % | Application |

|

ZQSnD10-1 |

Cu-10Sn-1p | Wear resisting parts under heavy duty and high sliding speed |

|

ZQSnD10-2 |

Cu-10Sn-2Zn | Complicated design casting, valves, pump, gear, and turbo |

|

ZQSnD10-5 |

Cu-10Sn-5Pb | structural material, anti corrosion and anti acid parts |

|

ZQSnD6-6-3 |

Cu-6Sn-6Zn-3Pb | Parts working under friction conditions, such as bushing. |

|

ZQSnD5-5-5 |

Cu-5Sn-5Zn-5Pb | Wear and corrosion resistant parts that operate under high loads and at moderate sliding speeds |

|

ZQPbD10-10 ZQPbD15-8 ZQPbD17-4-4 |

Cu-10Sn-10Pb | Automotive part and other heavy duty parts |

| Cu-15Pb-8Sn | Anti acid parts and parts working under high pressure. | |

| Cu-17Pb-4Sn-4Zn | High sliding speed bearing and general wear resistant parts | |

|

ZQMnD12-8-3 |

Cu-13Mn-8Al-3Fe | Heavy duty machinery bushing and high strength wear resistant, pressure loading part |

|

QMnD12-8-3-2 |

Cu-13Mn-8Al-3Fe-2Ni | High strength anti corrosion, wear resistant and pressure loading parts. |

|

ZQAlD9-4-4-2 |

Cu-9.4Al-4.5Fe-4.5Ni-1.5Mn | Anti corrision, high strength casting. Wear resistant and parts working in high temperature. |

The copper alloy with zinc as the main alloying element is usually called brass. Copper-zinc binary alloy called ordinary brass. With more alloy element added to the material based on copper-zinc alloy, it will be called special brass. Brass casting is widely applied in machinery industry, ship building, aerospace, automotive, construction, etc. The main characteristics of brass casting are wear resistance and anti rust features. Normal production methods for brass castings are die casting, centrifugal casting, lost wax casting and sand casting.

Product detail pictures:

Related Product Guide:

continue to enhance, to be certain solution top quality in line with market and buyer standard requirements. Our corporation has a excellent assurance program are actually established for Best quality Custom Forged Parts - Copper casting – Neuland Metals , The product will supply to all over the world, such as: Doha, Qatar, Juventus, The company has numbers of foreign trade platforms, which are Alibaba,Globalsources,Global Market,Made-in-china. "XinGuangYang" HID brand products sell very well in Europe, America, Middle East and other regions more than 30 countries.

The after-sale warranty service is timely and thoughtful, encounter problems can be resolved very quickly, we feel reliable and secure.