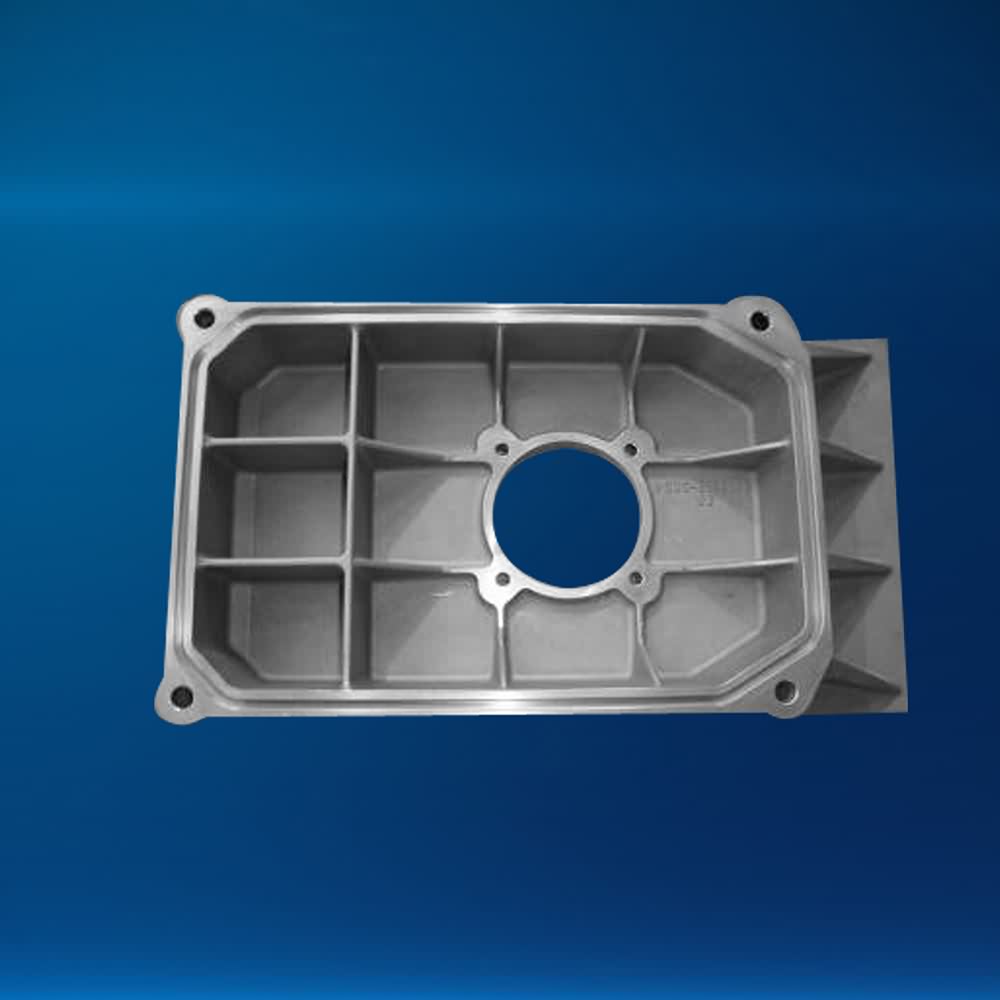

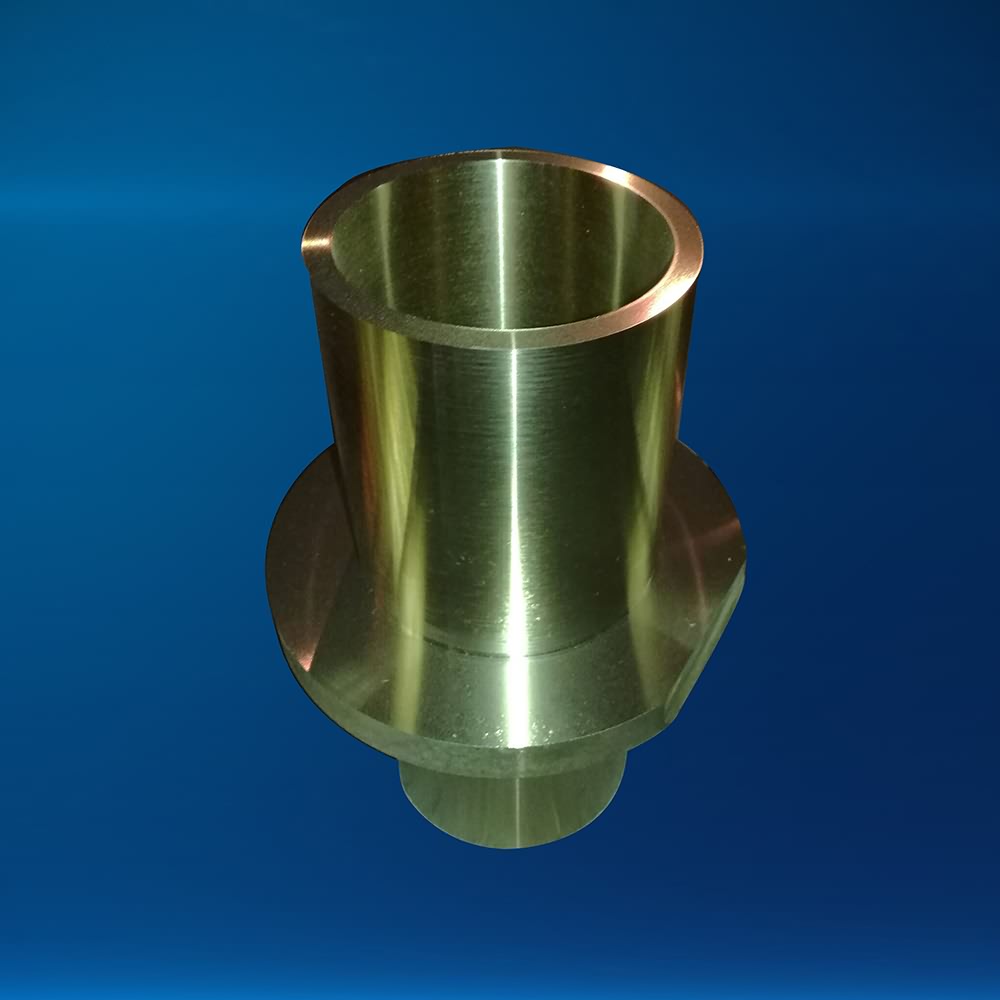

2020 New Style China Lost Wax Casting Factory - Copper casting – Neuland Metals

2020 New Style China Lost Wax Casting Factory - Copper casting – Neuland Metals Detail:

Bronze casting are a kind of copper alloy material which are widely used in the machinery manufacturing industry, ship building, automotive and construction industries. The most popular sorts of bronze castings can be classified as Cu-Sn, Cu-Al, Cu-Pb, Cu-Mn castings. Below are the common grade of

|

Grade |

Element % | Application |

|

ZQSnD10-1 |

Cu-10Sn-1p | Wear resisting parts under heavy duty and high sliding speed |

|

ZQSnD10-2 |

Cu-10Sn-2Zn | Complicated design casting, valves, pump, gear, and turbo |

|

ZQSnD10-5 |

Cu-10Sn-5Pb | structural material, anti corrosion and anti acid parts |

|

ZQSnD6-6-3 |

Cu-6Sn-6Zn-3Pb | Parts working under friction conditions, such as bushing. |

|

ZQSnD5-5-5 |

Cu-5Sn-5Zn-5Pb | Wear and corrosion resistant parts that operate under high loads and at moderate sliding speeds |

|

ZQPbD10-10 ZQPbD15-8 ZQPbD17-4-4 |

Cu-10Sn-10Pb | Automotive part and other heavy duty parts |

| Cu-15Pb-8Sn | Anti acid parts and parts working under high pressure. | |

| Cu-17Pb-4Sn-4Zn | High sliding speed bearing and general wear resistant parts | |

|

ZQMnD12-8-3 |

Cu-13Mn-8Al-3Fe | Heavy duty machinery bushing and high strength wear resistant, pressure loading part |

|

QMnD12-8-3-2 |

Cu-13Mn-8Al-3Fe-2Ni | High strength anti corrosion, wear resistant and pressure loading parts. |

|

ZQAlD9-4-4-2 |

Cu-9.4Al-4.5Fe-4.5Ni-1.5Mn | Anti corrision, high strength casting. Wear resistant and parts working in high temperature. |

The copper alloy with zinc as the main alloying element is usually called brass. Copper-zinc binary alloy called ordinary brass. With more alloy element added to the material based on copper-zinc alloy, it will be called special brass. Brass casting is widely applied in machinery industry, ship building, aerospace, automotive, construction, etc. The main characteristics of brass casting are wear resistance and anti rust features. Normal production methods for brass castings are die casting, centrifugal casting, lost wax casting and sand casting.

Product detail pictures:

Related Product Guide:

We have now sophisticated machines. Our solutions are exported to the USA, the UK and so on, enjoying a great reputation amid consumers for 2020 New Style China Lost Wax Casting Factory - Copper casting – Neuland Metals , The product will supply to all over the world, such as: Cambodia, Johor, Durban, The design, processing, purchasing, inspection, storage, assembling process are all in scientific and effective documentary process , increasing usage level and reliability of our brand deeply, which makes us become superior supplier of the four major product categories shell castings domestically and obtained the customer's trust well.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.