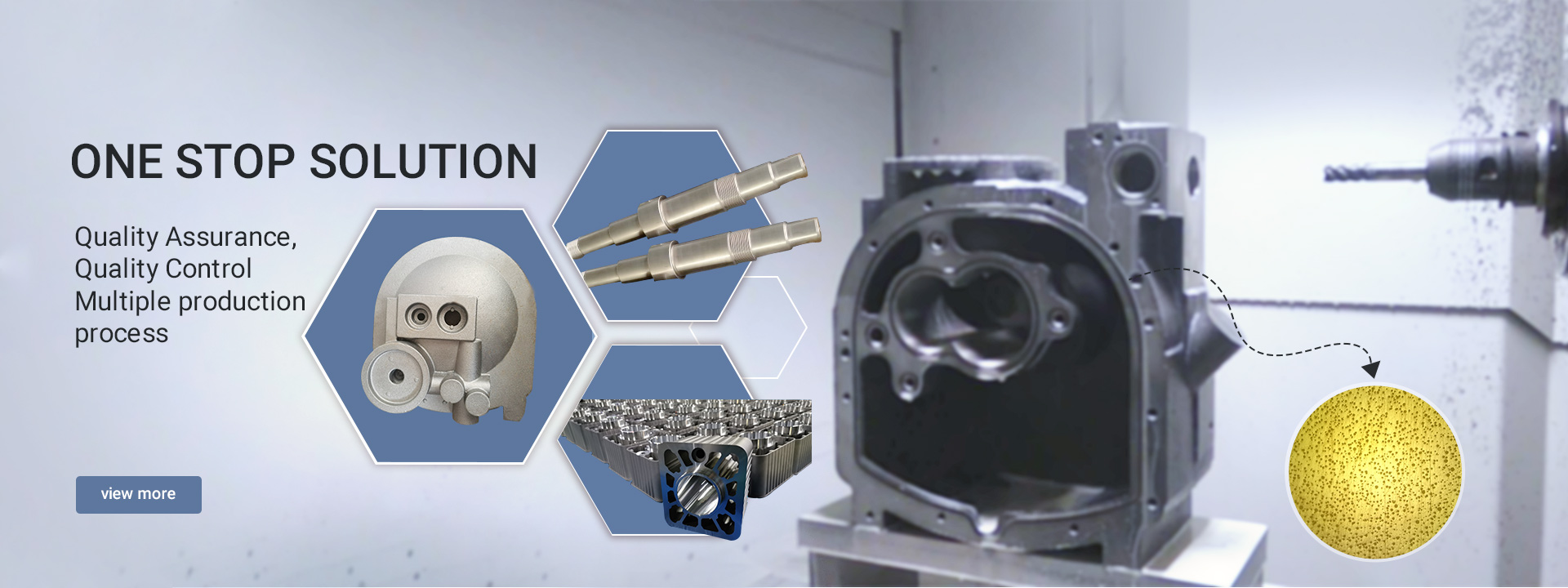

ABOUT US

Neuland is a company manufacturing and marketing of metal products for nearly 20 years.

The company has been supplying products in materials cast iron, steel, stainless steel, aluminum, copper etc by production methods sand casting, die casting, lost wax casting and die forging and precision machining. Assembling and surface coating service are also available.

And over the past years, the company has grown up as a whole process solution provider for any metal products in various industries. Either your drawings can be shaped into products, or even your idea can be realized into a satisfactory product starting designing to shipping. Moreover, our engineering team is capable and more than happy to provide our proposals to you on valuable change of production method and material to best fulfill the cost reduction and function of a product.

NEWS

-

Stainless Steel Welding

IV. Key Technical Points of Stainless Steel Welding (Core professional aspects) Welding Consumable Matching Welding wire or electrode must be compatible with the base material Example: AISI 304 base material matched with ER308L filler Heat Input Control ... -

The difference between 316 and 304 stainl...

The difference between 316 and 304 stainless steel casting 316 and 304 china precision casting stainless steel castings are widely used where corrosion resistance is required. 316 and 304 custom investment casting are widely used in everything from construction an... -

Welding Processes

Welding Processes: Types, Advantages, Disadvantages & Industrial Applications Welding is a critical fabrication technique used across industries, from automotive manufacturing to aerospace and construction. Choosing the right welding method can significantly impact produc... -

From Molten Metal to Finished Part: A Gui...

Aluminum’s versatility stems not only from its alloys but also from the wide array of manufacturing processes that shape it. Each technique offers unique advantages in terms of design freedom, production volume, mechanical properties, and cost. This guide explores key me... -

Shift Fork

The shift fork belongs to the operating mechanism, which connects and disconnects the transmission mechanism. For example, gear shifting fork, clutch shifting fork, such as changing the position of the slipping gear of the lathe to achieve speed change; or used in the mechanis...

LATEST PRODUCT

Get the latest news delivered daily!

Give us your email and you will be daily updated with the latest events, in detail!